Abstract

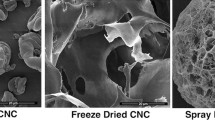

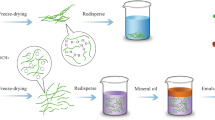

Cellulose nanocrystals (CNCs) are inherently hydrophilic; even so, their dispersions in water based applications such as rheology modifiers, coatings, and emulsion systems do not often produce perfect dispersions with a minimum energy input. Supplying the CNCs in dry granular powder form is needed in the industrial scale of production because of its easier handling, storage and transportation characteristics. Spray drying is the preferred industrial method for drying acid hydrolyzed CNC suspensions. However, spray drying often causes poor dispersion of dried CNC granules into individual nanoparticles in aqueous solutions if not mixed with high energy input. This study investigates foam-spray drying of CNC particles to enhance their dispersibility in water. Non-ionic 10-mole ethoxylated octylphenol surfactant (OPE-100) and methyl cellulose polymer (MC) were used as additives to assist the foaming of CNC suspensions. Foam-spray drying experiments were carried out under constant process conditions such as inlet and outlet temperatures, gas and liquid flow rates and concentrations of CNCs. We focus on the effects of 10-mole ethoxylated octylphenol surfactant (OPE-100) and methyl cellulose polymer (MC) as additives and foaming of CNCs suspension on the morphology of dried CNC aggregates and their dispersion in water. Our work also describes the molecular interaction mechanisms of CNCs with methyl cellulose and OPE-100 by means of isothermal titration calorimetry and surface charge of the coated CNCs. The addition of nonionic surfactant OPE-100 along with methyl cellulose polymer resulted in spray drying of CNC aggregates with the best water dispersion characteristics. While methyl cellulose generated foams, OPE-100 lowered the inverse thermal gelling of methyl cellulose in spray drying.

Graphic abstract

Similar content being viewed by others

References

Beck S, Bouchard J, Berry R (2012) Dispersibility in water of dried nanocrystalline cellulose. Biomacromolecules 13:1486–1494

Boluk Y, Zhao L, Incani V (2012) Dispersions of nanocrystalline cellulose in aqueous polymer solutions: structure formation of colloidal rods. Langmuir 28:6114–6123

Bück A, Peglow M, Naumann M, Tsotsas E (2012) Population balance model for drying of droplets containing aggregating nanoparticles. AIChE J 58:3318–3328

Cervin NT, Andersson L, Ng JB, Olin P, Bergström L, Wågberg L (2013) Lightweight and strong cellulose materials made from aqueous foams stabilized by nanofibrillated cellulose. Biomacromolecules 14:503–511

Clasen C, Kulicke W-M (2001) Determination of viscoelastic and rheo-optical material functions of water-soluble cellulose derivatives. Prog Polym Sci 26:1839–1919

Crook E, Trebbi G, Fordyce D (1964) Thermodynamic properties of solutions of homogeneous p, t-octylphenoxyethoxyethanols (OPE1-10). J Phys Chem 68:3592–3599

Frey D, King C (1986a) Effects of surfactants on mass transfer during spray drying. AIChE J 32:437–443

Frey DD, King CJ (1986b) Experimental and theoretical investigation of foam-spray drying. 1. Mathematical model for the drying of foams in the constant-rate period. Ind Eng Chem Fund 25:723–730

Hamad WY, Hu TQ (2010) Structure–process–yield interrelations in nanocrystalline cellulose extraction. Can J Chem Eng 88:392–402

Handscomb C, Kraft M, Bayly A (2009) A new model for the drying of droplets containing suspended solids. Chem Eng Sci 64:628–637

Hu Z, Xu R, Cranston ED, Pelton RH (2016) Stable aqueous foams from cellulose nanocrystals and methyl cellulose. Biomacromolecules 17:4095–4099

Hynninen V, Hietala S, McKee JR, Murtomäki L, Rojas OJ, Ikkala O, Nonappa N (2018) Inverse thermoreversible mechanical stiffening and birefringence in methylcellulose/cellulose nanocrystal hydrogel. Biomacromolecules 19:2795–2804

Khoshkava V, Kamal M (2014) Effect of drying conditions on cellulose nanocrystal (CNC) agglomerate porosity and dispersibility in polymer nanocomposites. Powder Technol 261:288-298

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Lintingre E, Lequeux F, Talini L, Tsapis N (2016) Control of particle morphology in the spray drying of colloidal suspensions. Soft Matter 12:7435–7444

Ngo T-D, Danumah C, Ahvazi B (2018) Production of cellulose nanocrystals at InnoTech Alberta. In: Nanocellulose and sustainability. CRC Press, Boca Raton, pp 269–287

Oguzlu H, Boluk Y (2017) Interactions between cellulose nanocrystals and anionic and neutral polymers in aqueous solutions. Cellulose 24:131–146

Oguzlu H, Danumah C, Boluk Y (2017) Colloidal behavior of aqueous cellulose nanocrystal suspensions. Curr Opin Colloid Interface Sci 29:46–56

Peng Y, Han Y, Gardner DJ (2012) Spray-drying cellulose nanofibrils: effect of drying process parameters on particle morphology and size distribution. Wood Fiber Sci 44:448–461

Ratti C, Kudra T (2006) Drying of foamed biological materials: opportunities and challenges. Dry Technol 24:1101–1108

Rumpf H (1962) The strength of granules and agglomerates. In: Agglomeration-proceedings of the first international symposium on agglomeration. Philadelphia, pp 379-418

Vehring R (2008) Pharmaceutical particle engineering via spray drying. Pharm Res 25:999–1022

Yuguchi Y, Urakawa H, Kitamura S, Ohno S, Kajiwara K (1995) Gelation mechanism of methylhydroxypropylcellulose in aqueous solution. Food Hydrocoll 9:173–179

Zbicinski I, Rabaeva J (2009) Analysis of gas admixing foam spray–drying process. Dry Technol 28:103–110

Acknowledgments

This research was supported by Natural Sciences and Engineering Research Council of Canada [Project NSERC CRD 492653-2015] and Alberta Innovates [Project AI-Bio 16-002 CRD]. The authors thank NSERC, Alberta Innovates and industrial partner FPInnovations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Esparza, Y., Ngo, TD., Fraschini, C. et al. Effects of additives on the particle morphology and aqueous dispersibility of foam-spray dried cellulose nanocrystal suspensions. Cellulose 26, 8611–8623 (2019). https://doi.org/10.1007/s10570-019-02675-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02675-8