Abstract

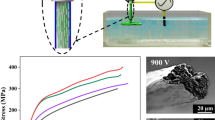

The development of nonwoven meshes based on cellulose acetate (CA) reinforced by cellulose nanocrystals (CNC) is reported. The meshes were electrospun from 15 wt% CA (Mn = 30,000) in dimethylacetamide/acetone (1:2, w/w) solutions with various concentrations of CNC dispersions. The investigated six levels of CNC dispersions in CA solutions were: 0, 0.075, 0.147, 0.225, 0.300 and 0.382 wt%, which corresponded to 0, 0.50, 1.00, 1.50, 1.99 and 2.55 wt% of CNC in solid fibers. The basis of the impact of CNC nano-particles on fiber diameter and morphology was explored by assessing their contributions to the viscosity, conductivity and homogeneity of CA/CNC solutions. CA/CNC nonwoven meshes spun from suspensions with 0.075 wt% CNC had best results in morphology and fiber uniformity. Additionally, mechanical properties of CA nonwoven meshes with five levels of CNC loading (0, 0.50, 1.00, 1.50 and 1.99 wt%) were examined. The CA nonwoven mesh with 0.50 wt% CNC showed best mechanical properties, and its elastic modulus (E) was improved to an average value of 1.68 GPa from 1.17 GPa of neat CA nanofiber nonwoven mesh. These improved meshes would have applications such as separation membranes, supports for catalysts and sensors, engineered tissues and other smart materials.

Similar content being viewed by others

References

Aoki D, Teramoto Y, Nishio Y (2007) SH-containing cellulose acetate derivatives: preparation and characterization as a shape memory-recovery material. Biomacromolecules 8:3749–3757

Boluk Y, Danumah C (2014) Analysis of cellulose nanocrystal rod lengths by dynamic light scattering and electron microscopy. J Nanoparticle Res 16:1–7

Boluk Y, Zhao L, Incani V (2012) Dispersions of nanocrystalline cellulose in aqueous polymer solutions: structure formation of colloidal rods. Langmuir 28:6114–6123

Brinkert L, Abidine N, Aptel P (1993) On the relation between compaction and mechanical properties for ultrafiltration hollow fibers. J Membr Sci 77:123–131

Chen Z, Wei B, Mo X, Lim C, Ramakrishna S, Cui F (2009) Mechanical properties of electrospun collagen–chitosan complex single fibers and membrane. Mater Sci Eng C 29:2428–2435

Chen C, Zhao Y, Liu W (2013) Electrospun polyethylene glycol/cellulose acetate phase change fibers with core–sheath structure for thermal energy storage. Renew Energy 60:222–225

Chew SY, Hufnagel TC, Lim CT, Leong KW (2006) Mechanical properties of single electrospun drug-encapsulated nanofibres. Nanotechnology 17:3880

De Vrieze S, Van Camp T, Nelvig A, Hagström B, Westbroek P, De Clerck K (2009) The effect of temperature and humidity on electrospinning. J Mater Sci 44:1357–1362

Dong H, Strawhecker KE, Snyder JF, Orlicki JA, Reiner RS, Rudie AW (2012) Cellulose nanocrystals as a reinforcing material for electrospun poly (methyl methacrylate) fibers: formation, properties and nanomechanical characterization. Carbohydr Polym 87:2488–2495

Ferrarezi MMF, Rodrigues GV, Felisberti MI, Gonçalves MdC (2013) Investigation of cellulose acetate viscoelastic properties in different solvents and microstructure. Eur Polym J 49:2730–2737

Gu SY, Wu QL, Ren J, Vancso GJ (2005) Mechanical properties of a single electrospun fiber and its structures. Macromol Rapid Commun 26:716–720

Guo J, Barbari TA (2010) A dual mode interpretation of the kinetics of penetrant-induced swelling and deswelling in a glassy polymer. Polymer 51:5145–5150

Gupta P, Elkins C, Long TE, Wilkes GL (2005) Electrospinning of linear homopolymers of poly(methyl methacrylate): exploring relationships between fiber formation, viscosity, molecular weight and concentration in a good solvent. Polymer 46:4799–4810

Halaui R, Moldavsky A, Cohen Y, Semiat R, Zussman E (2011) Development of micro-scale hollow fiber ultrafiltration membranes. J Membr Sci 379:370–377

Han SO, Youk JH, Min KD, Kang YO, Park WH (2008) Electrospinning of cellulose acetate nanofibers using a mixed solvent of acetic acid/water: effects of solvent composition on the fiber diameter. Mater Lett 62:759–762

Haward R, Thackray G (1968) The use of a mathematical model to describe isothermal stress-strain curves in glassy thermoplastics. Proc R Soc Lond A 302:453–472

Huang L, Arena JT, Manickam SS, Jiang X, Willis BG, McCutcheon JR (2014) Improved mechanical properties and hydrophilicity of electrospun nanofiber membranes for filtration applications by dopamine modification. J Membr Sci 460:241–249

Inai R, Kotaki M, Ramakrishna S (2005) Structure and properties of electrospun PLLA single nanofibres. Nanotechnology 16:208

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Konwarh R, Karak N, Misra M (2013) Electrospun cellulose acetate nanofibers: the present status and gamut of biotechnological applications. Biotechnol Adv 31:421–437

Lalia BS, Guillen E, Arafat HA, Hashaikeh R (2014) Nanocrystalline cellulose reinforced PVDF-HFP membranes for membrane distillation application. Desalination 332:134–141

Lim C, Tan E, Ng S (2008) Effects of crystalline morphology on the tensile properties of electrospun polymer nanofibers. Appl Phys Lett 92:141908

Lisunova M, Hildmann A, Hatting B, Datsyuk V, Reich S (2010) Nanofibres of CA/PAN with high amount of carbon nanotubes by core–shell electrospinning. Compos Sci Technol 70:1584–1588

Liu H, Hsieh YL (2002) Ultrafine fibrous cellulose membranes from electrospinning of cellulose acetate. J Polym Sci Part B Polym Phys 40:2119–2129

Liu H, Tang C (2006) Electrospinning of cellulose acetate in solvent mixture N,N-dimethylacetamide (DMAc)/acetone. Polym J 39:65–72

Lu P, Hsieh Y-L (2009) Cellulose nanocrystal-filled poly (acrylic acid) nanocomposite fibrous membranes. Nanotechnology 20:415604

Lu P, Hsieh Y-L (2010) Multiwalled carbon nanotube (MWCNT) reinforced cellulose fibers by electrospinning. ACS Appl Mater Interfaces 2:2413–2420

Ma Z, Ramakrishna S (2008) Electrospun regenerated cellulose nanofiber affinity membrane functionalized with protein A/G for IgG purification. J Membr Sci 319:23–28

Ma Z, Kotaki M, Ramakrishna S (2005) Electrospun cellulose nanofiber as affinity membrane. J Membr Sci 265:115–123

McKee MG, Wilkes GL, Colby RH, Long TE (2004) Correlations of solution rheology with electrospun fiber formation of linear and branched polyesters. Macromolecules 37:1760–1767

Nista SVG, Peres L, D’Ávila MA, Schmidt FL, Mei I, Lucia H (2012) Nanostructured membranes based on cellulose acetate obtained by electrospinning, part 1: study of the best solvents and conditions by design of experiments. J Appl Polym Sci 126:E70–E78

Park WI, Kang M, Kim HS, Jin HJ (2007) Electrospinning of poly(ethylene oxide) with bacterial cellulose whiskers. In: Kim BC, Ahn KD (eds) Macromolecular symposia, vol 1. Wiley, Weinheim, pp 289–294

Peresin MS, Habibi Y, Vesterinen A-H, Rojas OJ, Pawlak JJ, Seppälä JV (2010) Effect of moisture on electrospun nanofiber composites of poly(vinyl alcohol) and cellulose nanocrystals. Biomacromolecules 11:2471–2477

Ramires EC, Dufresne A (2011) A review of cellulose nanocrystals and nanocomposites. Tappi J 10:9–16

Reneker D, Yarin A, Zussman E, Xu H (2007) Electrospinning of nanofibers from polymer solutions and melts. Adv Appl Mech 41:43–346

Rodríguez K, Gatenholm P, Renneckar S (2012) Electrospinning cellulosic nanofibers for biomedical applications: structure and in vitro biocompatibility. Cellulose 19:1583–1598

Tan E, Ng S, Lim C (2005) Tensile testing of a single ultrafine polymeric fiber. Biomaterials 26:1453–1456

Tashiro K, Kobayashi M (1991) Theoretical evaluation of three-dimensional elastic constants of native and regenerated celluloses: role of hydrogen bonds. Polymer 32:1516–1526

Tungprapa S et al (2007) Electrospun cellulose acetate fibers: effect of solvent system on morphology and fiber diameter. Cellulose 14:563–575

Vallejos ME, Peresin MS, Rojas OJ (2012) All-cellulose composite fibers obtained by electrospinning dispersions of cellulose acetate and cellulose nanocrystals. J Polym Environ 20:1075–1083

Viet D, Beck-Candanedo S, Gray DG (2007) Dispersion of cellulose nanocrystals in polar organic solvents. Cellulose 14:109–113

Wang M, Jin H-J, Kaplan DL, Rutledge GC (2004) Mechanical properties of electrospun silk fibers. Macromolecules 37:6856–6864

Wang C, Hsu C-H, Lin J-H (2006) Scaling laws in electrospinning of polystyrene solutions. Macromolecules 39:7662–7672

Wei X, Xia Z, Wong S-C, Baji A (2009) Modelling of mechanical properties of electrospun nanofibre network. Int J Exp Comput Biomech 1:45–57

Wierenga AM, Philipse AP (1998) Low-shear viscosity of isotropic dispersions of (Brownian) rods and fibres; a review of theory and experiments. Colloids Surf A 137:355–372

Wong S-C, Baji A, Leng S (2008) Effect of fiber diameter on tensile properties of electrospun poly (ɛ-caprolactone). Polymer 49:4713–4722

Yu JH, Fridrikh SV, Rutledge GC (2006) The role of elasticity in the formation of electrospun fibers. Polymer 47:4789–4797

Yu D-G, Li X-Y, Wang X, Chian W, Liao Y-Z, Li Y (2013) Zero-order drug release cellulose acetate nanofibers prepared using coaxial electrospinning. Cellulose 20:379–389

Zhou C, Wu Q (2012) Recent development in applications of cellulose nanocrystals for advanced polymer-based nanocomposites by novel fabrication strategies. In: Neralla S (ed) Nanocrystals–synthesis, characterization, and applications. InTech, pp 103-120

Zhou C, Chu R, Wu R, Wu Q (2011a) Electrospun polyethylene oxide/cellulose nanocrystal composite nanofibrous mats with homogeneous and heterogeneous microstructures. Biomacromolecules 12:2617–2625

Zhou W, He J, Cui S, Gao W (2011b) Studies of electrospun cellulose acetate nanofibrous membranes. Open Mater Sci J 5:51–55

Zoppe JO, Peresin MS, Habibi Y, Venditti RA, Rojas OJ (2009) Reinforcing poly (ε-caprolactone) nanofibers with cellulose nanocrystals. ACS Appl Mater Interfaces 1:1996–2004

Acknowledgments

Authors would like to acknowledge personnel and equipment funding provided by NSERC and Canadian Foundation for Innovation (CFI) for the completion of this research project. Additionally, the CNC used in this research was provided by Alberta Innovates Technology Futures (AITF) in Edmonton, AB, Canada; therefore, the authors would like to thank AITF for the material provided.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Boluk, Y. & Ayranci, C. Investigation of nanofiber nonwoven meshes produced by electrospinning of cellulose nanocrystal suspensions in cellulose acetate solutions. Cellulose 22, 2457–2470 (2015). https://doi.org/10.1007/s10570-015-0665-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0665-4