Abstract

Despite tremendous advances in the field of tissue engineering, a number of obstacles are still hindering its successful translation to the clinic. One of these challenges has been to design cell-laden scaffolds that can provide an appropriate environment for cells to successfully synthesize new tissue while providing a mechanical support that can resist physiological loads at the early stage of in situ implementation. A solution to this problem has been to balance tissue growth and scaffold degradation by creating new hydrogel systems that possess both hydrolytic and enzymatic degradation behaviors. Very little is known, however, about the complex behavior of these systems, emphasizing the need for a rigorous mathematical approach that can eventually assist and guide experimental advances. This paper introduces a mathematical and numerical formulation based on mixture theory, to describe the degradation, swelling, and transport of extracellular matrix (ECM) molecules released by cartilage cells (chondrocytes) within a hydrogel scaffold. The model particularly investigates the relative roles of hydrolytic and enzymatic degradations on ECM diffusion and their impacts on two important outcomes: the extent of ECM transport (and deposition) and the evolution of the scaffold’s mechanical integrity. Numerical results based on finite element show that if properly tuned, enzymatic degradation differs from hydrolytic degradation in that it can create a degradation front that is key to maintaining scaffold stiffness while allowing ECM deposition. These results therefore suggest a hydrogel design that could enable successful in situ cartilage tissue engineering.

Similar content being viewed by others

References

Armstrong CG, Mow VC (1982) Armstrong CG, Mow VC (1982) Variations in the intrinsic mechanical properties of human articular cartilage with age, degeneration, and water content. J Bone Jt Surg Am 64:88–94

Ateshian GA (2007) On the theory of reactive mixtures for modeling biological growth. Biomech Model Mechanobiol 6:423–445

Bell CL, Peppas NA (1995) Biomedical membranes from hydrogels and interpolymer complexes. Adv Polym Sci 122:125–175

Bryant SJ, Anseth KS (2002) Hydrogel properties influence ECM production by chondrocytes photoencapsulated in poly(ethylene glycol) hydrogels. J Biomed Mater Res 56:63–72

Chen EI, Kridel SJ, Howard EW, Li W, Godzik A, Smith JW (2002) A unique substrate recognition profile for matrix metalloproteinase-2. J Biol Chem 277(6):4485–4491

Cowie JMG, Arrighi V (2008) Polymers: chemistry and physics of modern materials. CRC Press, Boca Raton

Deshmukh M et al (2010) Biodegradable poly(ethylene glycol) hydrogels based on a self-elimination degradation mechanism. Biomaterials 31:6675–6684

Dhote V, Skaalure S, Akalp U, Roberts J, Bryant SJ, Vernerey FJ (2012) On the role of hydrogel structure and degradation in controlling the transport of cell-secreted matrix molecules for engineered cartilage. Journal of the Mechanical Behavior of Biomedical Materials In Press, Accepted Manuscript, http://dx.doi.org/10.1016/j.jmbbm.2012.10.016

Dimicco MA, Sah RL (2003) Dependence of cartilage matrix composition on biosynthesis, diffusion, and reaction. Trans Porous Media 858:57–73

Flory PJ (1953) Principles of polymer chemistry. Cornell University Press, Ithaca

Haider MA, Olander JE, Arnold RF, Marous DR, McLamb AJ, Thompson KC, Woodruff WR et al (2011) A phenomenological mixture model for biosynthesis and linking of cartilage extracellular matrix in scaffolds seeded with chondrocytes. Biomech Model Mechanobiol 10(6):915–924

Holland TA et al (2007) Degradable hydrogel scaffolds for in vivo delivery of single and dual growth factors in cartilage repair. Osteoarthr Cartil OARS Osteoarthr Res Soc 15:187–197

Holmes MH, Mow VC (1990) The nonlinear characteristics of soft gels and hydrated connective tissues in ultrafiltration. J Biomech 23(11):1145–1156

Hong W, Liu Z, Suo Z (2009) Inhomogeneous swelling of a gel in equilibrium with a solvent and mechanical load. Int J Solids Struct 46:3282–3289

Hong W, Zhao X, Suo Z (2010) Large deformation and electrochemistry of polyelectrolyte gels. J Mech Phys Solids 58:558–577

Humphrey JD, Rajagopal KR, Program BE (2002) A constrained mixture model for growth and remodeling of soft tissues. Math Models Methods Appl Sci 12:407–430

Hutmacher DW, Sittinger M, Risbud MV (2004) Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol 22:354–362

Huyghe JM, Janssen JD (1999) Thermo-chemo-electro-mechanical formulation of saturated charged porous solids. J Porous Media 34: 129–141

Huyghe JM, Molenaar MM, Baajens FPT (2007) Poromechanics of compressible charged porous media using the theory of mixtures. J Biomech Eng 129:776–785

Ikada Y (2006) Challenges in tissue engineering. J R Soc Interface R Soc 3:589–601

Kestin J, Khalifa HE, Correia RJ (1981) Tables of the dynamic and kinematic viscosity of aqueous nael solutions in the temperature range 20–150 C and the pressure range 0.1–35 Mpa. J Phys Chem Ref Data 10(1):71–87

Klisch SM, Chen SS, Sah RL, Hoger AA (2003) Growth mixture theory for cartilage with application to growth-related experiments on cartilage explants. J Biomech Eng 125:169

Leskovac V (2003) Comprehensive enzyme kinetics. Kluwer Academic/Plenum Publisheds, New York

Lévesque SG, Shoichet MS (2007) Synthesis of enzyme-degradable, peptide-cross-linked dextran hydrogels. Bioconjug Chem 18:874–885

Lustig SR, Peppas NA (1988) Solute diffusion in swollen membranes. IX. Scaling laws for solute diffusion in gels. J Appl Polym Sci 36(4):735–747

Merrill EW, Dennison KA, Sung C (1993) Partitioning and diffbsion of solutes in hydrogels of poly(ethylene oxide). Biomaterials 14(15):1117–1126

Metters AT, Anseth KS, Bowman CN (2000a) Fundamental studies of a novel, biodegradable PEG-b-PLA hydrogel. Polymer 41:3993–4004

Metters AT, Bowman CN, Anseth KS (2000b) A Statistical kinetic model for the Bulk Degradation of PLA-b-PEG-b-PLA hydrogel networks. Society 104:7043–7049

Nicodemus GD, Bryant SJ (2008) Cell encapsulation in biodegradable hydrogels for tissue engineering applications. Tissue Eng Part B Rev 14:149–165

Slaughter BV, Khurshid SS, Fisher OZ, Khademhosseini A, Peppas NA (2009) Hydrogels in regenerative medicine. Adv Mater 21(32–33):3307–3329

Sun DN, Gu WY, Guo XE, Lai WM, Mow VC (1999) A mixed finite element formulation of triphasic mechano-electrochemical theory for charged hydrated biological soft tissues. Int J Numer Meth Eng 45:1375–1402

Thorne RG, Hrabetova S, Nicholson C (2005) Diffusion measurements for drug design. Nat Mater 4:713–714

Treloar LRG (1975) The physics of rubber elasticity. Oxford University Press, New York

Vernerey FJ, Greenwald EC, Bryant SJ (2011) Triphasic mixture model of cell-mediated enzymatic degradation of hydrogels. Comput Methods Biomech Biomed Eng 1:1–14

Vernerey FJ, Farsad M (2011) A constrained mixture approach to mechano-sensing and force generation in contractile cells. J Mech Behav Biomed Mater 4(8):1683–1699

Villanueva I, Hauschulz DS, Mejic D, Bryant SJ (2008) Static and dynamic compressive strains influence nitric oxide production and chondrocyte bioactivity when encapsulated in PEG hydrogels of different crosslinking densities. Osteoarthr Cartil OARS Osteoarthr Res Soc 16:908–918

Zhang J, Zhao X, Suo Z, Jiang H (2009) A finite element method for transient analysis of concurrent large deformation and mass transport in gels. J Appl Phys 105:093522

Acknowledgments

FJV greatfully acknowledges NIH Grant Number 1R21AR061011 in support of this work.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix: Galerkin form

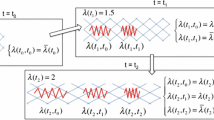

A mixed formulation is used with three-node elements for the solid phase and two-node elements for the other phases. The shape functions \(N\) and \(N_0\) and their derivatives \(B,\,B_1\) and \(B_0\) are defined in spherical coordinates (\(R,\theta ,\psi \)). The \(\psi \) direction shall not be needed because of the centro-symmetric assumption (same behavior in \(\theta \) and \(\psi \) directions). For example, the first Piola–Kirchhoff stress \(\mathbf{P}\) can be written \([P_{RR} \quad P_{\theta \theta }]^T\).

The shape functions are used to discretize the unknowns and weighting functions to derive weak form of the solid phase, alpha phase and the molecular incompressibility. They can be defined in spherical coordinates as:

Discretizing Eq. (27), (28) and (29) is done by injecting Eq. (30) in it. As a result, one can show that the equation of the solid (Eq. (27)) takes the following form:

The alpha phase (Eq. (28)) discretized form is derived:

Finally, the third equation comes from the molecular incompressibility equation (Eq. (29)). Namely:

Appendix: Linearized form

In order to solve for the unknown vector \(\mathbf{y}\) in Eqs. (32), (46), (47) and (48) are linearized. Here, \(\mathcal A ,\,e,\,n_\mathrm{{elt}}\) and \(n_\mathrm{{elt-front}}\) denote the assembly operation, element number, number of elements and the number of elements on the boundary (frontier). The unknown vector is written as \( \mathbf{y} =\begin{bmatrix} \mathbf{u}&[C^\alpha ]&[\pi ] \end{bmatrix}^T\).

1.1 Solid phase

The procedure to linearize the solid expression is to relate the first and the second Piola-Kirchhoff stresses using the expression below, and express the two terms as functions of the unknown fields (Eq (26)):

The latter equation enables to separate the contributions from the material and geometric stiffnesses. The linearized expression thus constitutes the finite element form,

where the stiffness \(\mathbf{K}_s\) ans the residual vector \(\mathbf{R}_s\) are defined as

The mechanical stiffness \(\mathbf{K}_\mathrm{{mech}}^\mathrm{{mech}}\) is the summation of the material \(\mathbf{K}_{\mathrm{{mech}},e}^\mathrm{{mat}}\) and geometrical \(\mathbf{K}_{\mathrm{{mech}},e}^\mathrm{{geo}}\) contributions, respectively coming from \(\delta \mathbf{S}\) and \(\delta \mathbf{F}\) (Eq. (49)). \(\mathbf{K}_{\mathrm{{mech}},e}^{\pi }\) comes from the osmotic pressure term in Eq. (12).

1.2 Alpha phase

The alpha phase equation is linearized after discretization. Thus, Eq. (47) gives

where the damping matrix \(\mathbf{C}_\alpha \), stiffness matrix \(\mathbf{K}_\alpha \) and residual vector \(\mathbf{R}_\alpha \) are defined as follows

The damping stiffnesses (\(\mathbf{C}_\alpha ^\mathrm{{mech}}\) and \(\mathbf{C}_\alpha ^\alpha \)) come from the time dependency in Eq. (15), and the stiffness matrices \(\mathbf{K}_\alpha ^\alpha \) and \(\mathbf{K}_\alpha ^\pi \) represent the stiffnesses from Ficks’s and Darcy’s law (Eq. 20).

1.3 Molecular incompressibility

Finally, Eq. (48) linearization results in the last equation:

where the stiffness matrix \(\mathbf{K}_\mathrm{{constr}}\) and residual vector \(\mathbf{R}_\mathrm{{constr}}\) are defined as follows

The stiffness matrix \(\mathbf{K}_\mathrm{{constr}}\) emphasizes that the constraint has an impact on both the solid (\(\mathbf{K}_\mathrm{{constr}}^\mathrm{{mech}}\)) and alpha phase (\(\mathbf{K}_\mathrm{{constr}}^\alpha \)). It comes, respectively, from the term \(J\) and \(\nu ^\alpha C^\alpha \) in Eq. (9).

Rights and permissions

About this article

Cite this article

Dhote, V., Vernerey, F.J. Mathematical model of the role of degradation on matrix development in hydrogel scaffold. Biomech Model Mechanobiol 13, 167–183 (2014). https://doi.org/10.1007/s10237-013-0493-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10237-013-0493-0