Abstract

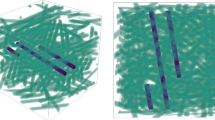

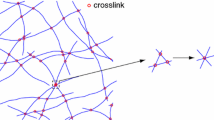

Attaining accurate representative geometry for a finite element analysis at various scales can be a challenging research task. Added complications arise when the geometry is representing a manufactured or biological composite. In this study, a representative geometry of linear fibrous composites was created at the microscale and is employed to reproduce crystalline microfibril stacking of Kevlar to form a single fibril joined by a non-ordered crystal structure. The structure can have ellipsoidal or rectangular microfibrils stacked in ellipsoidal or rectangular fibrils and may have any desired packing ratio within the 1–100% range. In order to build a fibrous structure along a path, a Random Walk methodology was used. Since the directionality of the fibers is random, but always stepping from one side of the path toward the other, the fibers can wind around each other and tangle or terminate if needed. Another key concept of this method is the addition of a rotation matrix operation for the path of the fibers. This allows the path around the three local coordinates to be in a linear or sinusoidal direction. The resultant geometry produced can represent the tortuous path nanofibrils undergo. Moreover, rotation about the path axis allows for the twisted geometry of ring spun yarn, and metal cable to be reproduced. Inclusion of spherical objects to the path of the fibers has been accommodated to reproduce fiber projection around, or end at, an obstruction in their path. This approach allows representing impurities at the fibril, fiber, or yarn level of composite fabric manufacturing.

Similar content being viewed by others

References

Iorga L., Pan Y., Pelegri A.A.: Analysis of 3D random chopped fiber reinforced composites using FEM and random sequential adsorption. Comput. Mater. Sci. 43(3), 450–461 (2008)

Feng X.-Q., Qin Q.-H., Yu S.-W.: Quasi-micromechanical damage model for brittle solids with interacting microcracks. Mech. Mater. 36, 261–273 (2004)

Hollister S.J., Kikuchi N.: A comparison of homogenization and standard mechanics analyses for periodic porous composites. Comput. Mech. 10, 73–95 (1992)

Liu Y.J., Chen X.L.: Evaluations of the effective material properties of carbon nanotube-based composites using a nanoscale representative volume element. Mech. Mater. 35, 69–81 (2003)

Li S., Thouless M.D., Waas A.M., Schroeder J.A., Zavattieri P.D.: Use of a cohesive-zone model to analyze the fracture of a fiber-reinforced polymer-matrix composite. Compos. Sci. Technol. 65, 537–549 (2005)

Shan B.X., Pelegri A.A., Pan Y.: Interfacial crack kinking subjected to contact effects. J. Mech. Mater. Struct. 3, 591–605 (2008)

Recchia, S.S., Pelegri, A.A., et. al: A hierarchical model for Kevlar fiber failure. In: Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition, p. 4 (2013)

Favier V., Dendievel R., Canova G.: Simulation and modeling of three-dimensional percolating structures: case of a latex matrix reinforced by a network of cellulose fibers. Acta Materialia 45, 1557–1565 (1997)

Chasiotis, W.K.I.: Experimentation at the Micron–Submicron Scale, Vol. 8, Comprehensive Structural Integrity, no. Interfacial and Nanoscale Failure, pp. 41–87. Elsevier, Amsterdam (2003)

Dobb, M., Johnson, D.J., Majeed, A., P.S.B: Microvoids in aramid type fibrous polymers. Polymer 20, 1284–1288 (1979)

Naraghi M., Ozkan I., Chasiotiis S.S., de Boer M.P., Hazra S.: MEMS platform for on-chip nanomechanical experiments with strong and highly ductile nanofibers. J. Micromech. Microeng. 20, 125022-1–125022-9 (2010)

Cousins S.K., Brown R.M.: Cellulose 1 microfibril assembly: computational molecular mechanics energy analysis favours bonding by van der Waals forces as the initial step in crystallization. Polymer 36, 3885–3888 (1995)

Jia X., Williams R.A.: A packing algorithm for particles of arbitrary shapes. Powder Technol. 129, 175–186 (2001)

Lee Y., Fang C., Tsou Y.-R., Lu L.-S., Yang C.-T.: A packing algorithm for three-dimensional convex particles. Granul. Matter 11, 307–315 (2009)

Nolan G.T., Kavanagh P.E.: Random packing of nonspherical particles. Powder Technol. 84, 199–205 (1995)

Gray W.A.: The Packing of Solid Particles. Chapman & Hall, London (1968)

Zhang, W.: Experimental and Computational Analysis of Random Cylinder Packings with Applications. A Dissertation Submitted to Louisiana State University and Agricultural and Mechanical College (2006)

Zhou G., Sun X.: Multi-chain digital element analysis in textile mechanics. Compos. Sci. Technol. 64, 239–244 (2003)

Lim T.-C.: Three-level hierarchical approach in modeling sheet thermoforming. Int. J. Mech. Sci. 45, 1097–1117 (2003)

Boubaker B., Haussy B., Ganghoffer J.-F.: Consideration of the yarn–yarn. Mech. Res. Commun. 34, 371–378 (2007)

D’Amato, E.: Finite element modeling of textile composites. Compos. Struct. 54, 467–475 (2001)

Verberne C.W.: Mechanical Modelling of Textitles. University of Technology, Eindhoven (2010)

Loikkanen, M., Praveen, G., Powell, D.: Simulation of Ballistic Impact on Composite Panels (2008)

Grujicic, M., Bell, W.C., Glomski, P.S., Pandurangan, B., Yen, C.F., Cheeseman, B.A.: Filament level modeling of aramid based high performance structural materials. J. Mater. Eng. Perform. 20, 1401–1413 (2011)

Altendorf H., Jeulin D.: Random walk based stochastic modeling of 3D fiber systems. Phys. Rev. 83, 10 (2010)

Berhan L., Sastry A.M.: Modeling percolation in high-aspect-ratio fiber systems. ii. The effect of waviness on the. Phys. Rev. 75, 041121 (2007)

Aboolfathi N., Naik A., Chafi M., Karami G., Ziejewski M.: A micromechanical procedure for modelling the anisotropic mechanical properties of brain white matter. Comput. Methods Biomech. Biomed. Eng. 12, 249–262 (2009)

Shreiber D.I., Hao H.L., Elias R.: Probing the influence of myelin and glia on the tensile properties of the spinal cord. Biomech. Model. Mechanobiol. 8, 311–321 (2009)

Pan, Y., Schreiber, D.I., Pelegri, A.A.: A transition model for finite element simulation on kinematics of central nervous system white matter. In: IEEE Transactions on Biomedical Engineering, Special Issue: Multi-Scale Modeling and Analysis for Computational Biology and Medicine (2011)

Johnson C.L., McGarry M., Gharibans A.A., Weaver J.B., Paulsen K.D., Wang H., Olivero W.C., Sutton B.P., Georgiadis J.G.: Local mechanical properties of white matter structures in the human brain. NeuroImage 79, 145–152 (2013)

Streitberger K.J., Wiener E., Hoffmann J., Freimann F.B., Klatt D., Braun J., Lin K., McLaughlin J., Sprung C., Klingebiel R., Sack I.: In vivo viscoelastic properties of the brain in normal pressure hydrocephalus. NMR Biomed. 24, 385–392 (2011)

Sandia National Labs, Cubit Home Page, 03 2012. (Online) www.cubit.sandia.gov/help-version13.2/Cubit_13.2_User_Documentation.pdf. Accessed 21 04 2013

Pan, Y., Patel, V., Pelegri, A.A., Shreiber, D.I.: Psuedo 3D RVE based finite element simulation on white matter. In: Proceedings of the ASME 2012 International Mechnical Engineering Congress and Exposition (2012)

Hamilton, B.J.: Process and Product Data Management for Staple Yarn Manufacturing, A thesis submitted to the Graduate Faculty, North Carolina State University (2010)

Zupin, Z., Dimitrovski, K.: Mechanical Properties of Fabrics Made from Cotton and Biodegradable Yarns Bamboo, SPF, PLA in Weft. Woven Fabric Engineering (2010)

Sierra Solid Mechanics Team: Presto 4.16 Users Guide. Sandia National Labs, Albuquerque (2010)

Majumdar A., Mukhopadhyay S.: Properties of ring spun yarns made from cotton and regenerated Bamboo. Indian J. Fibre Textile Res. 36, 18–23 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Recchia, S., Zheng, J. & Pelegri, A.A. Fiberwalk: a random walk approach to fiber representative volume element creation. Acta Mech 225, 1301–1312 (2014). https://doi.org/10.1007/s00707-013-1069-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-013-1069-x