Abstract

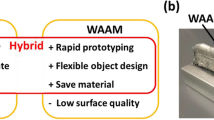

A robotized laser/wire directed energy deposition (RLW-DED) process has been employed, specifically in applications where higher deposition rates or larger buildup envelopes are needed. However, this process might have limitations in printing certain complex shape parts. Fabricating parts with overhang sections, depending on the geometry, might cause a collision between the laser head and the buildup. Part segmentation and joining the elements back together has been presented to overcome those limitations. In this study, the welding of additively manufactured parts by RLW-DED has been proposed. Autogenous laser welding, performed at the same setup used for RLW-DED, was utilized to join the thin-walled 316LSi DED parts. Mechanical and microstructural testing were then performed on the welded samples. The results showed that the mechanical properties of welded DED parts are comparable with those of DED parts. Furthermore, a component of complex shape was fabricated to show the capability of the developed process. Therefore, the welding of RLW-DED parts can expand the application of 3D-printed parts in industry.

Similar content being viewed by others

References

Additive Manufacturing—General Principles—Terminology (2015) ISO/ASTM 52900. International Organization for Standardization, Geneva

ASTM F3187–16, standard guide for directed energy deposition of metals, ASTM International, West Conshohocken, PA, 2016, www.astm.org

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire+ arc additive manufacturing. Mater Sci Technol 32(7):641–647

Abioye TE, McCartney DG, Clare AT (2015) Laser cladding of Inconel 625 wire for corrosion protection. J Mater Process Technol 217:232–240

Brandl E, Michailov V, Viehweger B, Leyens C (2011) Deposition of Ti–6Al–4V using laser and wire, part I: microstructural properties of single beads. Surf Coat Technol 206(6):1120–1129

Akbari M, Ding Y, Kovacevic R. Process development for a robotized laser wire additive manufacturing. In ASME 2017 12th International Manufacturing Science and Engineering Conference collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing 2017 Jun 4 (pp. V002T01A015-V002T01A015). American Society of Mechanical Engineers

Heralić A, Christiansson AK, Ottosson M, Lennartson B (2010) Increased stability in laser metal wire deposition through feedback from optical measurements. Opt Lasers Eng 48(4):478–485

Akbari M, Kovacevic R (2018) An investigation on mechanical and microstructural properties of 316LSi parts fabricated by a robotized laser/wire direct metal deposition system. Addit Manuf 23:487–497

Zhang J, Liou F (2004) Adaptive slicing for a multi-axis laser aided manufacturing process. J Mech Des 126(2):254–261

R. Dwivedi R, S. Zekovic, R. Kovacevic. A novel approach to fabricate uni-directional and branching slender structures using laser-based direct metal deposition. Int J Mach Tools Manuf 2007;47(7–8):1246–1256

Casalino G, Campanelli SL, Ludovico AD (2013) Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int J Adv Manuf Technol 68(1–4):209–216

Wits WW, Becker JJ (2015) Laser beam welding of titanium additive manufactured parts. Procedia CIRP 28:70–75

Matilainen VP, Pekkarinen J, Salminen A (2016) Weldability of additive manufactured stainless steel. Phys Procedia 83:808–817

Salminen A, Westin E, Lappalainen E, Unt A (2012) Effect of gas shielding and heat input on autogenous welding of duplex stainless steel. ICALEO2012

Berretta JR, de Rossi W, das Neves MD, de Almeida IA, Junior ND (2007) Pulsed Nd:YAG laser welding of AISI 304 to AISI 420 stainless steels. Opt Lasers Eng 45(9):960–966

Oshida Y (2010) Bioscience and bioengineering of titanium materials. Elsevier

Standard AS. E8," standard test methods for tension testing of metallic materials. Annual book of ASTM standards 2004;3:57–72

Yan J, Gao M, Zeng X (2010) Study on microstructure and mechanical properties of 304 stainless steel joints by TIG, laser and laser-TIG hybrid welding. Opt Lasers Eng 48(4):512–517

Cui CY, Cui XG, Ren XD, Liu TT, Hu JD, Wang YM (2013) Microstructure and microhardness of fiber laser butt welded joint of stainless steel plates. Mater Des 49:761–765

Silva CC, de Miranda HC, de Sant'Ana HB, Farias JP (2009) Microstructure, hardness and petroleum corrosion evaluation of 316L/AWS E309MoL-16 weld metal. Mater Charact 60(4):346–352

Kwok CT, Fong SL, Cheng FT, Man HC (2006) Pitting and galvanic corrosion behavior of laser-welded stainless steels. J Mater Process Technol 176(1–3):168–178

Vilpas M (1999) Prediction of microsegregation and pitting corrosion resistance of austenitic stainless steel welds by modelling. Technical Research Centre of Finland

Kobryn PA, Moore EH, Semiatin SL (2000) The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr Mater 43(4):299–305

Zambon A, Ferro P, Bonollo F (2006) Microstructural, compositional and residual stress evaluation of CO2 laser welded superaustenitic AISI 904L stainless steel. Mater Sci Eng A 424(1–2):117–127

Cao X, Jahazi M (2009) Effect of welding speed on butt joint quality of Ti–6Al–4V alloy welded using a high-power Nd: YAG laser. Opt Lasers Eng 47(11):1231–1241

Gao M, Zeng X, Yan J, Hu Q (2008) Microstructure characteristics of laser–MIG hybrid welded mild steel. Appl Surf Sci 254(18):5715–5721

Seto N, Katayama S, Matsunawa A (2000) High-speed simultaneous observation of plasma and keyhole behavior during high power CO 2 laser welding: effect of shielding gas on porosity formation. J Laser Appl 12(6):245–250

Katayama S, Kobayashi Y, Mizutani M, Matsunawa A (2001) Effect of vacuum on penetration and defects in laser welding. J Laser Appl 13(5):187–192

Acknowledgements

The authors would like to thank Andrew Socha, the research engineer at Research Center for Advanced Manufacturing, for his assistance during experimental works.

Funding

This study was supported by NSF’s Grant No. IIP-1539853.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbari, M., Kovacevic, R. Joining of elements fabricated by a robotized laser/wire directed energy deposition process by using an autogenous laser welding. Int J Adv Manuf Technol 100, 2971–2980 (2019). https://doi.org/10.1007/s00170-018-2891-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2891-z