Abstract

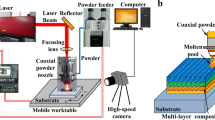

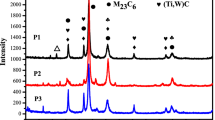

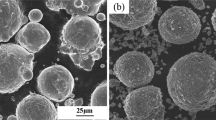

The erosion performance of laser cladded Ni-60 %WC coatings subjected to a controllable abrasive water jet (AWJ) was investigated. The erosion resistance of Ni-60 %WC coatings at varied linear laser energy (from 315 to 700 J/mm) was examined under different impinging angles of a slurry jet. The chemical composition of coatings was modified by nanocrystalline WC powder and the rare earth element (La2O3). The erosion value of Ni-60 %WC was reduced to 40 % by decreasing the laser energy from 700 to 315 J/mm. Synthesized coatings with optimal weight fraction of nano-WC particles (5 %) and La2O3 (1 %) decreased the average microstructural grain size of the Ni-binder, increased the homogeneity and hardness of the coating, and consequently increased the erosion resistivity. The tribological evaluation of the erosion scars showed a log-linear relationship between coating hardness and volume loss under erosion. Adding nano-WC (5 %) and La2O3 (1 %) enhanced the bonding strength between Ni and WC and no pulled out WC particles was observed after erosion test.

Similar content being viewed by others

References

Nøkleberg L, Søntvedt T (1995) Erosion in choke valves—Oil and gas industry applications. Wear 186:401–412

Walley SM, Field JE, Greengrass M (1987) An impact and erosion study of polyether etherketone. Wear 114:59–71

Levin BF, Vecchio KS, DuPont JN, Marder AR (1999) Modeling solid-particle erosion of ductile alloys. Metall Mater Trans A30(7):1763–1774

Upadhyaya GS (1998) Cemented tungsten carbides: production, properties and testing. William Andrew

Paul CP, Mishra SK, Tiwari P, Kukreja LM (2013) Solid-particle erosion behaviour of WC/Ni composite clad layers with different contents of WC particles. Opt Laser Technol 50:155–162

Gant AJ, Gee MG (2009) Structure–property relationships in liquid jet erosion of tungsten carbide hardmetals. Int J Refract Met Hard Mater 27(2):332–343

Meng H, Zhang Z, Zhao F, Qiu T (2013) Preparation of WC nanoparticles by twice ball milling. Int J Refract Met Hard Mater 41:191–197

Cho J, Joshi MS, Sun CT (2006) Effect of inclusion size on mechanical properties of polymeric composites with micro and nano particles. Compos Sci Technol 66(13):1941–1952

Yarrapareddy E, Kovacevic R (2008) Synthesis and characterization of laser-based direct metal deposited nano-particles reinforced surface coatings for industrial slurry erosion applications. Surf Coat Technol 202(10):1951–1965

Wang KL, Zhang QB, Sun ML, Wei XG, Zhu YM (2001) Rare earth elements modification of laser-clad nickel-based alloy coatings. Appl Surf Sci 174(3):191–200

Farahmand P, Liu S, Zhang Z, Kovacevic R (2014) Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La 2 O 3. Ceram Int 40(10):15421–15438

Parisa F, Balu P, Kong F, Kovacevic R (2013) Investigation of thermal cycle and hardness distribution in the laser cladding of AISI H13 tool steel produced by a high power direct diode laser. ASME 2013 International Mechanical Engineering Congress and Exposition. Am Soc Mech Eng

Mann BS, Vivek A, Pant BK (2013) High-power diode laser surface treated HVOF coating to combat high energy particle impact wear. J Mater Eng Perform 22(7):1995–2004

Farahmand P, Kovacevic R (2014) An experimental–numerical investigation of heat distribution and stress field in single-and multi-track laser cladding by a high-power direct diode laser. Opt Laser Technol 63:154–168

Zhou S, Huang Y, Zeng X, Qianwu H (2008) Microstructure characteristics of Ni-based WC composite coatings by laser induction hybrid rapid cladding. Mater Sci Eng A 480(1):564–572

Tian YS, Chen CZ, Chen LX, Huo QH (2006) Effect of RE oxides on the microstructure of the coatings fabricated on titanium alloys by laser alloying technique. Scr Mater 54(5):847–852

Zhao GM, Wang KL (2006) Effect of La2O3 on corrosion resistance of laser clad ferrite-based alloy coatings. Corros Sci 48(2):273–284

Kleis I, Kulu P (2008) Solid particle erosion. Occurrence, Prognosification and Control

Farahmand P, Kovacevic R (2014) Parametric study and multi-criteria optimization in laser cladding by a high power direct diode laser. Lasers Manuf Mater Proc 1(1–4):1–20

Wood RJK (2006) Erosion–corrosion interactions and their effect on marine and offshore materials. Wear 261(9):1012–1023

Gu D, Shen Y (2008) The role of La2O3 in direct laser sintering of submicrometre WC–Cop/Cu MMCs. J Phys D Appl Phys 41(9):095308

Ball A (1983) On the importance of work hardening in the design of wear resistant material. Wear 91:201

Fang ZZ, Wang X, Taegong R, Hwang KS, Sohn HY (2009) Synthesis, sintering, and mechanical properties of nanocrystalline cemented tungsten carbide—a review. Int J Refract Met Hard Mater 27(2):288–299

Castberg TS, Johnsen R, Berget J (2013) Erosion of hardmetals: Dependence of WC grain size and distribution, and binder composition. Wear 300(1):1–7

Balu P, Hamid S, Kovacevic R (2013) An experimental study on slurry erosion resistance of single and multilayered deposits of Ni-WC produced by laser-based powder deposition process. J Mater Eng Perform 22(11):3398–3413

Liu S, Farahmand P, Kovacevic R (2014) Optical monitoring of high power direct diode laser cladding. Opt Laser Technol 64:363–376

Kosel TH (1992) Solid particle erosion. ASM Handb 18:199–213

Wang KL, Zhang QB, Sun ML, Wei XG (2003) Microstructural characteristics of laser clad coatings with rare earth metal elements. J Mater Process Technol 139(1):448–452

Haghi AK, Oluwatobi SO, Josmin PJ, Hanna JM, eds (2013) Composites and nanocomposites. CRC Press

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farahmand, P., Frosell, T., McGregor, M. et al. Comparative study of the slurry erosion behavior of laser cladded Ni-WC coating modified by nanocrystalline WC and La2O3 . Int J Adv Manuf Technol 79, 1607–1621 (2015). https://doi.org/10.1007/s00170-015-6936-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6936-2