Abstract

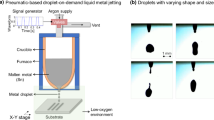

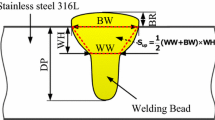

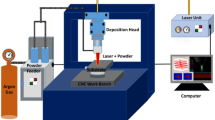

Laser-enhanced gas metal arc welding (GMAW) is a recent modification of conventional GMAW. It applies a low power laser to the droplet to obtain an auxiliary detaching force to help the detachment and achieve controlled metal transfer. As a primary parameter that affects the process and weld quality, the size of the droplet needs to be monitored and controlled. However, its direct measurement requires a high-speed camera and is not preferred in a manufacturing site because of its high cost and complicated system structure. Soft-sensing method was thus proposed as an alternative to obtain it in real time. Laser power intensity, wire feed speed and welding voltage were identified as the major parameters that determine the droplet size and were thus selected as the auxiliary variables to estimate the primary parameters: size and transfer rate of the droplet. Least squares (LS) regression equation, back-propagation neural network (BPNN), particle swarm optimization-based back-propagation neural network, and three swarm cooperative particle swarm optimization-based back-propagation neural network (TSCPSO-BPNN) models were established from the collected data. Simulation results were analyzed and compared among these models. It was found that the selected auxiliary variables were closely related to the primary variables. Droplet size and transfer rate estimates made based on the TSCPSO-BPNN model are similar to those based on LS regression equation. After dimension reduction, the LS equation can be simpler than TSCPSO-BPNN model while the accuracy is sufficient and meets the requirement for future control. The estimation by LS method could thus be utilized in the control of the laser-enhanced GMAW.

Similar content being viewed by others

References

Sadler H (1999) A look at the fundamentals of gas arc metal welding. Weld J 78(5):45–50

Thomsen JS (2006) Control of pulsed gas metal arc welding. Int J Model Identif Control 1(2):115–125

O’Brien RL (1991) Welding handbook vol. 2: welding processes, 8th edn. American Welding Society, Miami

Huang Y, Zhang YM (2010) Laser enhanced GMAW. Weld J 89(9):181s–188s

McAvoy TJ (1992) Contemplative stance for chemical process control. Automatica 28(2):441–442

Yu JJ, Zhou CH (1996) Soft-sensing techniques in process control. Control Theory Appl 13(2):137–144

Richalet J, Rault A, Testud JL, Papon J (1978) Model predictive heuristic control: applications to industrial processes. Automatica 14(5):413–428

Piotrowski K, Piotrowskib J, Schlesingerb J (2003) Modelling of complex liquid–vapour equilibria in the urea synthesis process with the use of artificial neural network. Chem Eng Process 42(4):285–289

Zhou Y, Hahn J, Mannan MS (2003) Fault detection and classification in chemical processes based on neural networks with feature extraction. ISA Trans 42(4):651–664

Liau LCK, Yang TCK, Tsai MT (2004) Expert system of a crude oil distillation unit for process optimization using neural networks. Expert Syst Appl 26(2):247–255

Lu CH, Tsai CC (2007) Generalized predictive control using recurrent fuzzy neural networks for industrial processes. J Process Control 17(1):83–92

Björck Å (1996) Numerical methods for least squares problems. SIAM, Philadelphia

Rumelhart DE, McClelland JL (1986) Parallel distributed processing: explorations in the microstructure of cognition. MIT Press, Cambridge

Moody J, Darken CJ (1988) “Learning with localized receptive fields,” Proceedings of the 1988 Connectionist Models Summer School

Moody J, Darken CJ (1989) Fast learning in network of locally-tuned processing units. Neural Comput 1:281–294

Hagan MT, Demuth HB, Beale MH (2002) Neural network design. PWS, Boston

Colorni A, Dorigo M, and Maniezzo V, (1991) “Distributed optimization by ant colonies,” Proc. of First European Conference on Artificial Life, pp 134-142. Paris, France

Dorigo M, Stützle T (2004) Ant colony optimization. MIT Press, Cambridge

Kirkpatrick S, Gelatt CDJ, Vecchi MP (1983) Optimization by simulated annealing. Science 220:671–680

Millonas MM (1994) “Swarm, phase transition, and collective intelligence,” Artificial life III. Addison Wesley, MA

Eberhart R, Kennedy J (1995) “A new optimizer using particle swarm theory,” Proceedings of the sixth international symposium on micro machine and human science (Nagoya, Japan). IEEE, Piscataway, pp 39–43

Kennedy J, Eberhart R (1995) “Particle swarm optimization”, Proceedings of the IEEE international conference on neural networks, IV. IEEE, Piscataway, pp 1942–1948

Kim TH, Maruta I, Sugie T (2008) Robust PID controller tuning based on the constrained particle swarm optimization. Automatica 44(4):1104–1110

Goh CK, Tan KC, Liu DS, Chiam SC (2010) A competitive and cooperative co-evolutionary approach to multi-objective particle swarm optimization algorithm design. Eur J Oper Res 202(1):42–54

Sabat SL, Ali L, Udgata SK (2011) Integrated learning particle swarm optimizer for global optimization, Appl Soft Comput 11(1):574–584

Tandon V, (2001) “Closing the Gap between CAD/CAM and Optimized CNC End Milling,” Master’s thesis, Purdue School of Engineering and Technology, Indiana University Purdue University

Wang SH, Feng NQ, Li AG (2003) A BP networks learning algorithm based on PSO. Comput Appl Softw 20(8):74–76

Chau KW (2007) Application of a PSO-based neural network in analysis of outcomes of construction claims. Autom Constr 16(5):642–646

Liu ZQ, Gu XS, Chen GC (2006) Three swarms cooperative particle swarm optimization. J East China Univ Sci Technol 32(7):754–757

Wang XW, Gu XS, Liu ZQ, Shang YQ (2009) Soft sensing model of C3 concentration of FCCU based on PSO-BP Neural Network. J Syst Simul 21(4):973–976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Huang, Y. & Zhang, Y. Droplet transfer model for laser-enhanced GMAW. Int J Adv Manuf Technol 64, 207–217 (2013). https://doi.org/10.1007/s00170-012-4014-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4014-6