Abstract

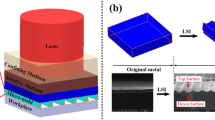

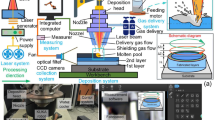

To improve the forming quality of parts fabricated by laser direct metal forming (LDMF), the forming process of three-dimensional parts under open-loop LDMF system was studied in this paper. The influencing rule of scanning space on the forming quality was studied, and the optimal scanning space was derived. The software of control system about scanning style is also optimized, and thus, the forming quality of parts is improved. During fabricating three-dimensional parts, uneven heat distribution caused by multi-overlapping is one of the main factors affecting the sidewall forming quality. To solve the uneven heat distribution, the strategy of changing scanning speed was put forward. The influence of the standoff distance on the height of single-trace cladding layer was studied, and it was suggested that uneven surface of parts was caused by instability of process parameters, which could be compensated automatically in the condition of suitable standoff distance in the process of LDMF. Thus a so-called self-regulation effect is reached. Typical multi-overlapped parts with good forming quality are fabricated using the above-mentioned methods.

Similar content being viewed by others

References

Griffith ML, Keicher DM, Atwood CL, Romero JA, Smugeresky JE, Harwell LD, Greene DL (1996) Free form fabrication of metallic components using laser engineered net shaping (LENS(TM)). Solid Freeform Fabrication Proceedings 9:125–131

Smugeresky JE, Keicher DM, Romero JA, Griffith ML, Harwell LD (1997) Laser engineered net shaping (LENS™) process: optimization of surface finish and microstructural properties. Proceedings of the World Congress on Powder Metallurgy and Particulate Materials, Chicago, IL. 9:1–11

Milewski JO, Lewis GK, Thoma DJ, Keel GI, Nemec RB, Reinert RA (1998) Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J Mater Process Technol 75(1–3):165–172. doi:10.1016/S0924-0136(97)00321-X

Mah R (1997) Directed light fabrication. Adv Mater Process 151(3):31–33

Mazumder J, Choi J, Nagarathnam K, Koch J, Hetzner D (1997) The direct metal deposition of H13 tool steel for 3-D components. The Member Journal of the Minerals, Metals and Materials Society 49(5):55–60

Li YM (2003) The influences of processing parameters on forming characterizations during laser rapid forming. Mater Sci Eng A 360:18–25. doi:10.1016/S0921-5093(03)00435-0

Zhang K, Liu WJ, Shang XF (2007) Research on the processing experiments of laser metal deposition shaping. Opt Laser Tech 39:549–557. doi:10.1016/j.optlastec.2005.10.009

Milewski JO, Dickerson PG, Nemec RB, Lewis GK, Fonseca JC (1999) Application of a manufacturing model for the optimization of additive processing of Inconel alloy 690. J Mater Process Tech 91:18–28. doi:10.1016/S0924-0136(98)00412-9

Bi GJ, Gasser A, Wissenbach K, Drenker A, Poprawe R (2006) Characterization of the process control for the direct laser metallic powder deposition. Surf Coating Tech 201(6):2676–2683. doi:10.1016/j.surfcoat.2006.05.006

Zhang A, Li D, Zhou Z, Zhu G, Lu B (2010) Numerical simulation of powder flow field on coaxial powder nozzle in laser metal direct manufacturing. Int J Adv Manuf Tech 49:853–859. doi:10.1007/s00170-010-2657-8

Mazumder J, Dutta D, Kikuchi N, Ghosh A (2000) Closed loop direct metal deposition: art to part. Optic Laser Eng 34:397–414. doi:10.1016/S0143-8166(00)00072-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pi, G., Zhang, A., Zhu, G. et al. Research on the forming process of three-dimensional metal parts fabricated by laser direct metal forming. Int J Adv Manuf Technol 57, 841–847 (2011). https://doi.org/10.1007/s00170-011-3404-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3404-5