Abstract

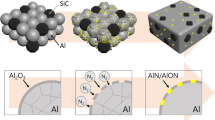

The present investigation demonstrated the feasibility of using reactive atomization to produce Si powder within situ oxide sintering aids. With further process optimization, this powder may be an alternative starting material to the conventional, mechanically blended, Si-plus-oxide powder used to produce commercial sintered reaction bonded silicon nitride (SRBSN). In the reactive atomization approach, yttrium and aluminum additives were introduced into silicon metal during induction melting. Reactive atomization was accomplished using a N2-5 pct O2 mixture as the atomization gas. During atomization, oxygen in the atomization gas reacted with Y and Al in the Si melt to produce Y2O3 and Al2O3, which act asin situ sintering aids. The reactive atomized powder demonstrated a Gaussian distribution with a mean diameter of 36 μm. The powder fines (<38 μm) were used to produce cold isostatically pressed compacts that were subsequently reaction bonded and sintered. The results demonstrate that β-Si3N4 formed during reaction bonding and sintering. The density of the SRBSN was 77 pct of theoretical. Transmission electron microscopy (TEM) studies indicated the presence of a glassy phase on the grain boundaries, which is typical in SRBSN and indicative of the presence of thein situ sintering aids. A kinetic model was used to study the influence of processing parameters, such as droplet temperature and oxygen partial pressure, on the kinetics of oxide formation during reactive atomization. The results suggest that the volume fraction of oxides increases with increasing droplet temperature and oxygen partial pressure in the atomization gas mixture.

Similar content being viewed by others

References

R.N. Katz:Mater. Technol., 1993, vol. 8, p. 142.

R.M. Williams and A. Ezis:Ceram. Bull., 1983, vol. 62, p. 607.

R.L. Riley:Sprechsaal, 1985, vol. 118, p. 225.

S. Somiya, M. Mitomo, and M. Yoshimura:Silicon Nitride—1, Elsevier Science Publishers, New York, NY, 1990.

J.A. Mangels: inProgress in Nitrogen Ceramics, F. Riley, ed., Martinus Nijhoff Publishing, Boston, MA, 1983, p. 231.

M. Torti: inCeramics for High Performance Applications III, E.M. Lenoe, R.N. Katz, and J.J. Burke, eds., Plenum Press, New York, NY, 1979, p. 261.

G.E. Gazza and R.N. Katz:MRS Symp. Proc, 1992, vol. 251, p. 199.

A.J. Moulson:J. Mater. Sci., 1979, vol. 14, p. 1017.

F.L. Riley:Progr. Nitrogen Ceram., 1983, p. 121.

H.M. Jennings:J. Mater. Sci., 1983, vol. 18, p. 951.

S.M. Boyer and A.J. Moulson:J. Mater. Sci., 1978, vol. 13, p. 1637.

W.R. Moser, D.S. Briere, R. Correia, and G.A. Rossetti:J. Mater. Res., 1978, vol. 2, p. 797.

J. Mangels:Ceram. Eng. Sci. Proc, 1981, vol. 2, p. 596.

A. Giachello and P. Popper:Ceram. Int., 1979, vol. 5, p. 110.

J.A. Mangels and G.J. Tennenhouse:Ceram. Bull., 1980, vol. 59, p. 1216.

E.J. Lavernia, T.S. Srivatsan, and R.H. Rangel:Atomiz. Sprays, 1992, vol. 2, p. 253.

X. Zeng, E.J. Lavernia, and J.M. Schoenung:Scripta Metall. Mater., 1995, vol. 32, p. 1203.

J.S. Kim, H. Schubert, and G. Petzow:J. Eur. Ceram. Soc., 1989, vol. 5, p. 311.

E.A. Brandes and G.B. Brook:Smithells Metals Reference Book, 7th ed., Butterworth-Heinemann Ltd., Oxford, United Kingdom, 1992.

H. Liu, R.H. Rangel, and E.J. Lavernia:Acta Metall. Mater., 1994, vol. 42, p. 3277.

X. Zeng, H. Liu, M.G. Chu, and E.J. Lavernia:Metall. Trans. A, 1992, vol. 23A, pp. 3394–99.

H. Liu, X. Zeng, and E.J. Laverania:Scripta Metall., 1993, vol. 29, p. 1341.

X. Zeng, S.R. Nutt, and E.J. Lavernia:Metall. Mater. Trans. A, 1995, vol. 26A, p. 817.

H.A. Johnson and M.W. Rubesin:Trans. ASME, 1949, vol. 71, p. 447.

W.E. Ranz and W.R. Marshall:Chem. Eng. Prog, 1952, vol. 48, p. 141.

K.H. Jack: inProgress in Nitrogen Ceramics, F.L. Riley, ed., Martinus Nijhoff, Leyden, 1977, p. 45.

M. Prokesova and Z. Panek:J. Mater. Sci., 1990, vol. 25, p. 3709.

O. Abe:J. Mater. Sci., 1990, vol. 25, p. 3641.

G. Woetting, H. Feuer, and E. Gugel:Silicon Nitride Ceramics, Scientific and Technological Advances, I.W. Chen, P.F. Becher, M. Mitomo, G. Petzow, and T.S. Yen, eds., MRS, Boston, MA, 1992, p. 133.

M. Mitomo and S. Uenosono:J. Am. Ceram. Soc., 1992, vol. 75, p. 103.

F.F. Lange:Am. Ceram. Soc. Bull., 1983, vol. 62, p. 1369.

M.K. Cinibulk, H.J. Kleebe, G.A. Schneider, and M. Ruble:J. Am. Ceram. Soc., 1993, vol. 76, p. 2801.

M.E. Washburn and W.S. Coblenz:Ceram. Bull, 1988, vol. 62, p. 356. $

Author information

Authors and Affiliations

Additional information

This article is based on a presentation made in the “In Situ Reactions for Synthesis of Composites, Ceramics, and Intermetallics” symposium, held February 12–16, 1995, at the TMS Annual Meeting in Las Vegas, Nevada, under the auspices of SMD and ASM-MSD (the ASM/TMS Composites and TMS Powder Materials Committees).

Rights and permissions

About this article

Cite this article

Wu, Y., Zeng, X., Lavernia, E.J. et al. Reactive atomization of silicon to formin situ oxide sintering aids. Metall Mater Trans A 27, 2115–2121 (1996). https://doi.org/10.1007/BF02651866

Issue Date:

DOI: https://doi.org/10.1007/BF02651866