Abstract

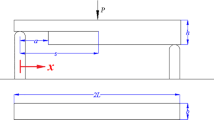

In the single-fiber-composite (SFC) test, a fiber imbedded in a matrix is loaded in tension, resulting in a fragmentation of the fiber. In the conventional version of this test, the final fiber fragmentation length distribution is used with a micro-mechanical model to determine the average fiber/matrix interfacial shear stress. In the enhanced version of this test, one also determines the applied stress at each fiber fracture, and from this, one can evaluate the strength of the fiber at short gage lengths. In our measurement system, we utilize an acoustic emission (AE) technique to detect the fiber fractures and to locate the fiber breaks and so determine both the fiber failure stresses as well as the fiber fragmentation lengths while the test is in progress. Critical to the success of this test is a broadband AE system that utilizes point-like AE sensors, procedures for evaluatingin situ, the wavespeed of the first wave arrival and signal processing techniques for determining the arrival time of this signal as precisely as possible for a broad range of wave shapes. Here we describe the application of such an enhanced SFC test procedure to investigate the failure of a Nicalon™ fiber in an epoxy matrix.

Similar content being viewed by others

References

S. L. Phoenix and L. J. Tierney,Eng. Fract. Mech. 18193–215 (1983).

B. W. Rosen,AIAA J. 2(11):1985–1991 (1964).

L. T. Drzal, M. J. Rich, and P. F. Lloyd,J. Adhes. 161–30 (1982).

L. T. Drzal, M. J. Rich, M. F. Koenig, and P. F. Lloyd,J. Adhes. 16133–152 (1983).

S. H. Own, R. V. Subramanian, and S. C. Saunders,J. Matler Sci. 213912–3920 (1986).

W. D. Bascom and R. M. Jensen,J. Adhes. 19219–239 (1986).

A. N. Netravali, R. B. Henstenburg, S. L. Phoenix, and P. Schwartz,Polym. Compos. 10226–241 (1989).

W. A. Curtin,J. Matler. Sci. 265239–5253 (1991).

A. N. Netravali, S. L. Phoenix, and P. Schwartz,Polym. Compos. 10385–388 (1989).

A. Kelly and W. R. Tyson,J. Mech. Phys. Solids 13329–350 (1965).

A. Kelly,Proc. Roy. Soc. Lond. A:31995–116 (1970).

R. B. Henstenburg and S. L. Phoenix, Interfacial shear strength studies using the single-filament-composite test II: A probability model and Monte-Carlo simulation.Poly. Compos. 10385–388 (1989).

W. Weibull, A Statistical Theory of the Strength of Materials, Handlinger, Royal Swedish Academy of Engineering Sciences, No. 151, Stockholm, 1939.

L. T. Drzal, 15th National SAMPE Tech. Conf., 1983, p. 190.

A. N. Netravali, Z.-F. Li, W. Sachse, and H. F. Wu,J. Matler. Sci. 266631–6638 (1991).

A. N. Netravali, L. T. T. Topoleski, W. Sachse, and S. L. Phoenix,Compos. Sci. Tech. 3513–29 (1989).

Y. L. Petitcorps, R. Pailer, and R. Naslain,Compos. Sci. Tech. 35207–214 (1989).

B. T. Ma, L. S. Schadler, C. Laird, and J. C. Figueroa,Polym. Compos. 11211–216 (1990).

W. Sachse, K. Y. Kim, and P. Hsieh,Advances in Fracture Research (Vol. 5), K. Salama, K. Ravi-Chandar, D. M. R. Taplin and P. Rama, eds. (ICF-7, Pergamon Press, Oxford, 1989), pp. 3185–3196.

B. Yavin, H. E. Gallis, J. Scherf, A. Eitan, and H. D. Wagner,Polym. Compos. 12(6):436–446 (1991).

M. C. Waterbury and L. T. Drzal,J. Comp. Test. Tech. Res. 13(1):22–28 (1991).

H. D. Wagner and A. Eitan,Appl. Phys. Lett. 561965–1967 (1990).

W. Sachse, A. G. Every, and M. O. Thompson, Impact of laser pulses on composite materials, inImpact Response and Elastodynamics of Composites (AMD-Vol. 116), A. K. Mal and Y. D. S. Rajapakse, eds. (ASME, New York, 1990), pp. 51–62.

K. Y. Kim and W. Sachse, InUI'89: Conference Proceedings (Butterworth Scientific, Guildford, Surrey, U.K. 1989), pp. 18–24.

K. Y. Kim and W. Sachse,J. Acoust. Soc. Am. 86(3):875–884 (1989).

K. Y. Kim and W. Sachse,Ultrasonics 25195–203 (1987).

A. G. Every, W. Sachse, and M. O. Thompson, Materials characterization from elastic wave anisotropy images, inUltrasonic Materials Characterization IV, C. O. Ruud and R. E. Green, eds. (Plenum Press, New York, 1991), pp. 493–500.

A. C. Cohen,Technometrics 7(4):579–588 (1965).

H. Lee,Handbook of Epoxy Resins (McGraw-Hill, New York, 1967).

Dow Corning Corporation, Information About NICALON™ Ceramic Fiber, 1989).

A. G. Metcalfe and G. K. Schmitz,Proc. 67th Meeting of the ASTM (ASTM, Philadelphia, Pennsylvania, 1964), pp. 1075–1093.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sachse, W., Netravali, A.N. & Baker, A.R. An enhanced, acoustic emission-based, single-fiber-composite test. J Nondestruct Eval 11, 251–261 (1992). https://doi.org/10.1007/BF00566415

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00566415