Abstract

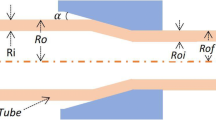

In forming a large automobile sheet metal part in a draw die, a blank is first clamped by curved binders to form a binder wrap. This paper presents a numerical method to calculate the binder wrap. Theanalysis domain, aliaspseudo blank, is the portion of the blank which goes into the die cavity. Since its boundary is not known in advance, an iteration method is used to calculate the pseudo blank and binder wrap simultaneously.

Given a pseudo blank, each iteration cycle consists of two steps: calculation of the binder wrap from the pseudo blank subjected to boundary displacements, and correction of the pseudo blank. Two examples are presented. The calculated results for both examples closely match the measured data. In the first example, correct results were obtained in the initial calculation showing the correctness of the initial selection of the pseudo blank. For the second example, convergent results were obtained in one iteration.

Similar content being viewed by others

References

K.K. Chen, “A numerical method for computing the sheet shape in the blank holding stage of a draw die,” ASME Paper 84-WA/DE-6, ASME Winter Annual Meeting, 1984.

S.C. Tang, “Computer prediction of the deformed shape of a draw blank during the binder-wrap stage,”J. Applied Metalworking, ASM, vol. 1, pp. 22–29, 1980.

N.K. Mital, “Prediction of binder wrap in sheet metal stampings using finite element method,” Proc. 1983 International Computers in Engineering Conference and Exhibit, ASME, pp. 71–77, 1983.

H. Ishigaki, I., Okamoto, N. Nakagawa, and K. Arima, “Analysis of growth and disappearance of surface deflection in press forming of large-sized autobody panels,”Int. J. of Vehicle Design, vol. 6, no. 2, 1985.

R.A. Ayres, “Technology transfer: making it really happen,” SAE Paper #860127, SAE Transactions, Society of Automotive Engineers, 1986.

M. Higashi, T. Mori, H. Taniguchi, and J. Yoshimi, “Geometric modelling for efficient evaluation of press forming severity,” In N.-M. Wang and S. C. Tang (eds.),Computer Modeling of Sheet Metal Forming Process, The Metallurgical Society, Inc., pp. 21–36, 1986.

N.-M. Wang and B. Budiansky, “Analysis of sheet metal stamping by a finite element method,”J. Appl. Mech., Trans. ASME, Vol. 100, 1978, pp. 73–82.

F.J. Arlinghaus, T.B. Stoughton, W.H. Frey, and B.K. Murthy, “Finite element modeling of a stretch-formed part,” In N.-M. Wang and S.C. Tang (eds.),Computer Modeling of Sheet Metal Forming Process, The Metallurgical Society, Inc., pp. 51–64, 1986.

S.C. Tang, “Verification and applications of a binder wrap analysis,” In N.-M. Wang and S.C. Tang (eds.),Computer Modeling of Sheet Metal Forming Process, The Metallurgical Society, Inc., pp. 193–208, 1986.

W.J. Gordon, “Free-form surface interpolation through curve networks,” General Motors Research Publication GMR-921, 1969.

J. A. Wixom, “Blending function interpolation over non-rectangular domains,” General Motors Research Publication GMR-1957, 1975.

I.D. Faux and M.J. Pratt,Computational Geometry for Design and Manufacturing, Ellis Harwood, Ltd., Chichester, England, 1979.

S.C. Tang, E. Chu, and S.K. Samanta, “Finite element prediction of the deformed shape of an automobile body panel during deformed stage,” Proceedings International Conference on Numerical Method in Industrial Forming Processing, Eds. J.F.T. Pittman, et al., Swansea, United Kingdom, pp. 629–640, July, 1982.

J.C. Nagtegaal and J.G. Slater, “A simple noncompatible thin shell element based on discrete Kirchhoff theory,” presented at ASME Winter Annual Meeting, Washington, D.C., 1981.

K.-K. Chen, “Evaluation of a finite element for binder wrap calculations,” General Motors Research Publication GMR-5209, 1985.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, K.K. A new finite element method for binder wrap calculations. J. Materials Shaping Technology 5, 107–116 (1987). https://doi.org/10.1007/BF02834809

Issue Date:

DOI: https://doi.org/10.1007/BF02834809