Abstract

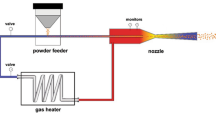

Spray forming involves sequential gas atomization of a melt into a spray of fine droplets and their deposition on a substrate to build up a high-density preform. The rapid solidification inherent in spray deposition generates refined, equiaxed and low segregation microstructures. A number of promising features of this near-net shape manufacturing process are highlighted and compared, wherever possible, with the conventional casting and PM techniques. Some commercial nozzles used to create spray and mechanisms associated with spray generation are described. The consolidation of the droplets and the development of the microstructure in the deposit are primarily governed by the nature of the spray and the thermal state of droplets on the deposition surface. Several microstructural characteristics of the deposit are presented and their origin in spray deposition is discussed.

Similar content being viewed by others

References

Anantharaman T R and Suryanarayana C 1971J. Mater. Sci. 6 1111

Ando T, Lavernia E J and Grant N J 1986Mater. Letts. 5 17

Beddow J K 1978 inThe production of metal powders, (London: Hyden & Sons)

Bewley B P and Cantor B 1990Met. Trans. B21 899

Bewley B P and Cantor B 1991J. Mater. Res. 6 1433

Bricknell R H 1986Met. Trans. A17 583

Brooks R G, Leatham A G, Coombs J S and Moore C 1977aMetall. Met. Form. 9 1

Brooks R G, Moore C, Leatham A G and Coombs J S 1977bPowder Met. 2 100

Chen H S and Miller C E 1970Rev. Sci. Instrum. 41 1237

Clyne T W, Ricks R A and Goodthew P J 1984Int. J. Rapid Solidification 1 59

Duszczyk J and Estrada J L 1990J. Mater. Sci. 25 1381

Gordon G D 1959J. Appl. Phys. 30 1759

Grant N J 1978 inRapid solidification processing: principle and technology, (eds) R Mehrabian, B H Kear and M Cohen (Baton Rouge: Claitor’s Pub. Div.) p. 230

Guitierrez E, Lavernia E J, Trapaga G, Izekely J and Grant N J 1989Met. Trans. 20 71

Ikawa Y 1990ISIJ Int. 30 756

Jones H 1973Rep. Progr. Phys. 36 1425

Jones H 1986Proc. Structural metals by rapid solidification, (eds) F H Froes and S J Savage (Orlando: ASM International) p. 77

Kim M H and Jones H 1981Rapidly quenched metals IV, (eds) T Masumoto and K Suzuki (Sendai: The Japan Institute of Metals) p. 85

Klar E and Fesko J W 1984Metals Handbook, (Metals Park, OH: ASM) Vol. 7, p. 25

Kurten J 1978 inBubbles, drops and particles, (New York: Academic Press)

Lane W R 1951Indian Engg. Chem. 43 1312

Lavernia E J 1989Int. J. Rapid Solidification 5 47

Lavernia E J and Grant N J 1986Mat. Powder Rep. 4 255

Lavernia E J and Grant N J 1988Mat. Sci. Engg. 98 381

Lawley A 1986J. Metals 38 15

Lawley A, Mathur P, Apelian D and Meystel A 1990Powder Met. 33 109

Leatham A F, Elias L and Ogilvy A 1991Met. Powder Rep. 46 38

Lubanska H 1970J. Metals 22 45

Magusar J, Lavernia E J, Domalavage P, Harling O K and Grant N J 1984J. Nucl. Mater. 122–123 789

Mathur P, Annavarapu S, Apelian D and Lawley A 1991Mater. Sci. Engg. A142 261

Mathur P, Apelian D and Lawley A 1989Acta Met. 37 429

Ojha S N, Jha J N and Singh S N 1991Scr. Met. Mater. 25 443

Ojha S N, Pandey O P, Tripathi B, Kumar M and Ramachandra C 1992Mater. Trans. JIM (in press)

Ojha S N and Satyanarayana K G 1992 (unpublished work)

Ojha S N and Singh S N 1991J. Mater. Sci. Letts. 10 893

Pandey O P and Ojha S N 1991Powder Met. Int. 23 291

Ranz W E and Marshall W R 1952Chem. Engg. Prog. 48 173

Rickinson B A, Kirk F A and Davies D R G 1981Powder Met. 1 1

Ricks R A, Adkins N J E and Cyne T W 1986Powder Met. 29 27

Savage S J and Froes F H 1984J. Metals 36 20

See J B and Johnston G H 1978Powder Tech. 21 118

Singer A R E 1970Met. Mater. 4 246

Singer A R E 1972J. Inst. Met. 100 185

Singer A R E and Evans R W 1983Met. Technol. 10 61

Singh S N 1991Development and analysis of an atomization process for spray deposition, Ph. D. thesis, Banaras Hindu University, Varanasi

Singh S N and Ojha S N 1991Metals, Materials & Processes 3 53

Singh S N, Mishra N S and Ojha S N 1992Steel Res. 63 12

Szekely J 1979Fluid flow in metals processing, (New York: Academic Press) p. 261

Taylor G I 1950Proc. R. Soc. A201 192

Unal A 1987Mater. Sci. Technol. 3 1029

Unal A 1989Met. Trans. B20 61

Williams B 1980Met. Powder Rep. 10 464

Wolf H E and Anderson W H 1965Proc. 5th Int. Shock tube symposium, p. 1153

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ojha, S.N. Spray forming: Science and technology. Bull. Mater. Sci. 15, 527–542 (1992). https://doi.org/10.1007/BF02747543

Issue Date:

DOI: https://doi.org/10.1007/BF02747543