Abstract

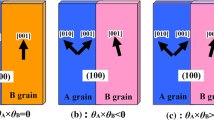

The formation and selection processes in dendritic microstructures that occur during the welding of two differently oriented Fe-15 wt pct Ni-15 wt pct Cr single-crystal pieces were analyzed. The specimens were oriented by X-ray diffraction and cut along precise crystallographic orientations in order to weld specific surfaces in a manner that joined two distinct, predetermined crystallographic directions. Six orientation configurations were selected in the present investigation: an (001) surface with a [100] or [110] direction, an (011) surface with a [100], [011], or [2\(\left[ {2\overline 1 1} \right]\)11] direction, and a (111) surface with a [\(\left[ {2\overline 1 \overline 1 } \right]\)11] direction. Using all of the possible combinations of two different crystal orientations(i.e., 15 combinations), two crystal halves were welded along their boundary using an electron beam to form longitudinal bicrystal welds. Experimental and simulated metallographic sections have been directly compared for six of the 15 bicrystal weld configurations. The dendritic pattern observed in transverse metallographic sections was analyzed for each single-crystal half on the basis of a selection criterion that had been developed previously for single-crystal welds;i.e., at a given location in the melt pool, the selected 〈100〉 dendrite trunk has the minimum undercooling or, equivalently, the minimum velocity. In general, the bicrystal weld microstructure is a simple composite of microstructures expected in each of the two single-crystal halves. However, near the weld centerline, it was shown that grain competition between dendrites belonging to different single crystals also occurred according to this same minimum undercooling criterion.

Similar content being viewed by others

References

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner:Metall. Trans. A, 1989, vol. 20A, pp. 1125–38.

S.A. David, J.M. Vitek, M. Rappaz, and L.A. Boatner:Metall. Trans. A, 1990, vol. 21A, pp. 1753–66.

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner:Metall. Trans. A, 1990, vol. 21A, pp. 1767–82.

A. Matsunawa, S. Katayama, and H. Simidzu:Trans. JWRI, 1990, vol. 19, pp. 67–77.

H. Esaka: Ph.D. Thesis No. 615, Ecole Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 1986.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rappaz, M., Vitek, J.M., David, S.A. et al. Microstructural formation in longitudinal bicrystal welds. Metall Trans A 24, 1433–1446 (1993). https://doi.org/10.1007/BF02668211

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02668211