Abstract

In a solar kiln the energy supply is limited and variable. To make the best possible use of the available energy, kiln control should be optimized. Several control parameters were investigated in a fully automated solar kiln. It was found that the venting rate and vent control were of major importance while very little spraying was required.

Zusammenfassung

Die Energieversorgung eines Solartrockners ist beschränkt und veränderlich. Um diese verfügbare Energie am besten zu nutzen, sollte das Klima im Solartrockner optimal gesteuert werden. Verschiedene Steuergrößen wurden in einem vollautomatischen steuerbaren Solartrockner untersucht, wobei sich herausstellte, daß die Leistung und Steuerung der Belüfter, im Gegensatz zur Befeuchtung, von großer Bedeutung sind.

Similar content being viewed by others

Literature

Chen, P.Y.S. 1981: Design and tests of a 500 BF solar kiln. For. Prod. J. 31(3):33–38

Forrer, J.B. 1981: Solar drying kilns—practical consideration for a mpu-based control system. Puls, September: 16–18, 122

Gough, D.K. 1977: The design and operation of a solar timber kiln. Fiji Timbers and their Uses (Department of Forestry, Suva) (67):1–17

Little, R.L. 1981: Effect of weather on dry kiln venting losses. For. Prod. J 31(6):4–44

Lumley, T.G.; Choong, T. 1981: Solar drying of wood in Louisiana. Louisiana State University and Agricultural and Mechanical College, Bulletin No. 732:2–55

Oliveira, L.C. de S.; Skaar, C.; Wengert, E.M. 1982: Solar and air lumber crying during winter in Virginia. For. Prod J. 32(1):37–44

Schneider, A.; Engelhardt, F.; Wagner, L. 1979: Vergleichende Untersuchungen über die Freilufttrocknung und Solartrocknung von Schnittholz unter mitteleuropäischen Wetterverhältnissen. Teil 1: Versuchsanlage und Ergebnisse der ersten Trocknungsversuche. Holz Roh-Werkstoff 37:427–433

Sharma, S.N.; Nath, P.; Bali, B.I. 1972: A solar timber seasoning kiln. Journal of the Timber Development Association of India 18(2):10–26

Simpson, W.T.; Tschernitz, J.L. 1977: Solar lumber dryer designs for developing countries. Paper presented at the workshop on the “Practical Application of Solar Energy to Wood Processing”, at Virginia Polytechnic Institute and State University, Blacksburg, Virginia, January 6–7:56–61

Simpson, W.T.; Tschernitz, J.L. 1984: Solar dry kiln for tropical latitudes. For. Prod. J. 34(5):25–34

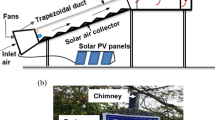

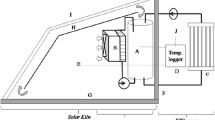

Steinmann, D.E.; Vermaas, H.F.; Forrer, J.B. 1980: Solar timber drying kilns: Part I: Review of previous systems and control measures and a description of an automatic solar kiln. J. Inst. of Wood Sci. 8(6):254–257

Steinmann, D.E.; Vermaas, H.F.; Forrer, J.B. 1981: Solar timber drying kilns: Part II: Micro processor control of a solar kiln. J. Inst. of Wood Sci. 9(1):27–31

Troxell, H.E.; Mueller, L.A. 1968: Solar lumber drying in the Central Rocky Mountain Region. For. Prod. J. 18(1):19–24

Author information

Authors and Affiliations

Additional information

This paper contains results from a PhD Thesis by D.E. Steinmann under the direction of Prof. H. F. Vermaas, Department of Wood Science, University of Stellenbosch, Republic of South Africa

Rights and permissions

About this article

Cite this article

Steinmann, D.E., Vermaas, H.F. Control of equilibrium moisture content in a solar kiln. Holz als Roh-und Werkstoff 48, 147–152 (1990). https://doi.org/10.1007/BF02627301

Issue Date:

DOI: https://doi.org/10.1007/BF02627301