Conclusions

-

1.

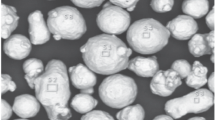

Liquid-phase laser sintering based on Rapid Prototyping technology can be successfully used on powder steel 3Kh3F12, the structure of which has a high concentration of a low-melting carbide eutectic. No low-melting additives are needed in this case.

-

2.

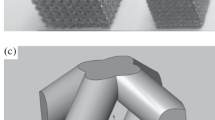

Optimization of the parameters of the laser fusion of powder steel for the duration of the production process makes it possible to obtain small compact specimens (5 mm in diameter and 30 mm in length).

-

3.

Sintered specimens of steel 3Kh3F12 have a microstructure of ledeburite and martensite with 15% vanadium carbides and 16% residual austenite.

-

4.

Despite the high cooling rates (100–1000°C/sec), multicomponent segregation along grain boundaries is seen in the specimens after the laser treatment.

Similar content being viewed by others

References

H. L. Marcus, J. J. Beaman, J. W. Barlow, and D. L. Bourell, “From computer to component in 15 minutes: The integrated manufacture of three-dimensional objects,”J. Met., April, 8–10 (1990).

U. Lakshimarayan and H. L. Markus, “An experimental study of relationship between microstructure and mechanical properties of ceramic composites fabricated by selective laser sintering,” in:Proceed. of the Solid Freeform Fabrication Sympos., H. L. Marcus, J. J. Beaman, J. W. Barlow, et al., Univ. of Texas Press, Austin, Texas (1992), pp. 44–53.

P. Subramannian, Kamatchi Zong, and H. L. Marcus, “Selective laser sintering of ceramic composites,” in:Proceed. of the Solid Freeform Fabrication Sympos., H. L. Marcus, J. J. Beaman, J. W. Barlow, et al., Univ. of Texas Press, Austin, Texas (1992), pp. 63–71.

U. Lakshminarayan,Dissertation: University of Texas, Austin (1992).

D. L. Vainshtein and A. I. Kovalev, “Modeling structural and phase transformations during the heat treatment and hot rolling of low- and medium-carbon medium-alloy structural steels,”Metallurg, No. 6, 44–46 (1999).

Additional information

“Poverkhnost” Scientific-Technical Center (of the Central Scientific Research Institute of Ferrous Metallurgy), A. A. Baikov Institute of Metallurgy (of the Russian Academy of Sciences), the Moscow Technical Institute STANKIN, and the Institute of Technical Acoustics (of the National Academy of Sciences of Belarus). Translated from Metallurg, No. 4, pp. 43–45, April, 2000.

Rights and permissions

About this article

Cite this article

Kovalev, A.I., Vainshtein, D.L., Mishina, V.P. et al. Selective laser sintering of steel powders to obtain products based on SAPR-models. Metallurgist 44, 206–209 (2000). https://doi.org/10.1007/BF02466080

Issue Date:

DOI: https://doi.org/10.1007/BF02466080