Abstract

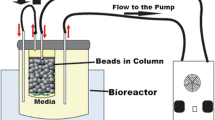

When the immobilized cells are employed in packed-bed bioreactors several problems appear. To overcome these drawbacks, a new bioreactor based on the use of pulsed systems was developed [1]. In this work, we study the glucose fermentation by immobilized Saccharomyces cerevisiae in a packed-bed bioreactor. A comparative study was then carried out for continuous fermentation in two packed-bed bioreactors, one of them with pulsed flow. The determination of the axial dispersion coefficients indicates that by introducing the pulsation, the hydraulic behaviour is closer to the plug flow model. In both cases, the residence time tested varied from 0.8 to 2.6 h. A higher ethanol concentration and productivity (increases up to 16%) were achieved with the pulsated reactors. The volumes occupied by the CO2 were 5.22% and 9.45% for fermentation with/without pulsation respectively. An activity test of the particles from the different sections revealed that the concentration and viability of bioparticles from the two bioreactors are similar. From the results we conclude that the improvements of the process are attributable to a mechanical effect rather than to physiological changes of microorganisms.

Similar content being viewed by others

Abbreviations

- D m2/s:

-

dispersion coefficient

- K is l/g:

-

inhibition substrate constant

- K ip l/g:

-

inhibition ethanol constant

- K s g/l:

-

Apparent affinity constant

- P g/l:

-

ethanol concentration

- q p g/(gh):

-

specific ethanol productivity

- Q p g/(lh):

-

overall ethanol productivity

- q s g/(gh):

-

specific glucose consumption rate

- Q s g/(lh):

-

glucose consumption rate

- S g/l:

-

residual glucose concentration

- S(in0) g/l:

-

initial glucose concentration

- V max g/(lh):

-

maximum rate

- Y p/s g/g:

-

yield in product

References

Sanromán, A.; Chamy, R.; Nuñez, M. J.; Lema, J. M.: Enzymatic hydrolysis of starch in a fixed-bed pulsed flow reactor. Appl. Biochem. Biotechnol. 28/29 (1991) 527–538

Roca, E.; Sanromán, A.; Núñez, M. J.; Lema, J. M.: Determination of axial dispersion coefficients in a fixed packed-bed pulsed flow bioreactor. 5th Mediterranean Congress on Chemical Engineering. Barcelona. P4.525 (1990) 564–565

Lema, J. M.; Nuñez, M. J.; Sanromán, A.; Roca, E.: Dispositivo de pulsación para ser acoplado a equipos de fermentación, reactores enzimáticos o reactores químicos. Spanish Patent: P 9200315. (1991)

Chamy, R.; Nuñez, M. J.; Lema, J. M.: Optimization of hardening treatment of S. cerevisiae bioparticles. Enzyme Microb. Technol. 12 (1990) 749–754

Bernfeld, P. D.: Enzymes of starch degradation and synthesis. Adv. Enzymol. 12 (1951) 379–427

Veiga, M. C.; Soto, M.; Mendez, R.; Lema, J. M.: A new device for measurement and control of gas production by bench scale anaerobic digesters. Wat. Res. 24 (1990) 1551–1554

Levespiel, O.: Chemical Reaction Engineering. New York. Wiley 1983

Bouzas, S.; Casares, J. J.; Lema, J. M.: Análisis de reactores de flujo no ideal. II. Ajuste a modelos de un solo parámetro. Ingeniería Química. 235 (1988) 115–120

Daugulis, A. J.; Swaine, D. E.: Examination of substrate and product inhibition kinetics on the production of ethanol by suspended and immobilized cell reactors. Biotechnol. Bioeng. 29 (1987) 639–645

Bunday, B. D.: Basic Optimization Methods. London. E. Arnold Pu. 1984

Dourado, A.; Goma, G.; Albuquerque, U.; Sevely, Y.: Modelling and static optimization of the ethanol production in a cascade reactor. Biotechnol. Bioeng. 29 (1987) 187–194

Ghose, T. K.; Tyagy, R. D.: Rapid ethanol fermentation of cellulose hydrolysate. I. Batch versus continuous systems. Biotechnol. Bioeng. 21 (1979) 1387–1400

Ghose, T. K.; Tyagy, R. D.: Rapid ethanol fermentation of cellulose hydrolysate. II. Product and substrate inhibition and optimization of fermenter design. Biotechnol. Bioeng. 21 (1979) 1401–1420

Gòdia, F.; Casas, C.; Solà, C.: Mathematical modelling of a packed-bed reactor performance with immobilized yeast for ethanol fermentation. Biotechnol. Bioeng. 30 (1987) 836–843

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sanromán, A., Roca, E., Núñez, M.J. et al. A pulsing device for packed-bed bioreactors: II. Application to alcoholic fermentation. Bioprocess Engineering 10, 75–81 (1994). https://doi.org/10.1007/BF00393389

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00393389