Abstract

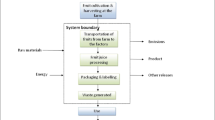

Nowadays there is a growing concern about the environmental effects produced by human activities due to natural resource depletion and ecosystem degradation. Traditionally, many industrial sectors have attempted to reduce the environmental impacts of their activities mainly by focusing their efforts on the improvement of manufacture procedures and operations carried out from the entry of raw materials in the factory to the exit of done products. However, for an adequate evaluation of the environmental performance of processes and products, it is necessary to think beyond the factory gate and understand the full life cycle of a product or an activity. Therefore, not only manufacture step should be taken into account but also other stages such as extraction and production of the required raw materials, packing and distribution of manufactured products, the use of products, the reuse or recycling processes and/or management of produced wastes. All these steps constitute the product life cycle, and the evaluation methodology that includes all of them is called life cycle assessment (LCA). Thus, life cycle assessment is considered a “cradle-to-grave” approach for the evaluation of industrial systems. In particular, systems for food production require larger inputs of resources and cause several negative environmental effects. Moreover, retailers are becoming very influential in addressing the environmental issue, exerting pressure on the food manufacturers to adopt sustainable manufacturing processes. Hence, sustainable processing is becoming increasingly important. A review of main LCA studies addressing environmental impacts in food industry, specifically in the vegetable processing industry, has been described. A “cradle-to-gate” case study considering as functional unit 130 g of packed RTE lettuce produced in Spain has been carried out. The main environmental burden obtained was associated with the processing phase (water used for lettuce washing; polypropylene used for packaging; and electricity consumed, mainly for cooling, in the processing plant), leading to emissions of 72 g CO2-eq affecting the global warming potential category.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Andersson K, Ohlsson T, Olsson P (1998) Screening life cycle assessment (LCA) of tomato ketchup: a case study. J Clean Prod 6:277–288

Bare JC (2002) The tool for the reduction and assessment of chemical and other environmental impacts. J Ind Ecol 6(3–4):49–78

Beccali M, Cellura M, Iudicello M, Mistretta M (2009) Resource consumption and environmental impacts of the agrofood sector: Life Cycle Assessment of Italian citrus-based products. Environ Manag 43:707–724

Boustead I (1996) LCA—how it came about the beginning in the UK. Int J Life Cycle Assess 1(3):147–150

Calderón LA, Iglesias L, Laca A, Herrero M, Díaz M (2010) The utility of Life Cycle Assessment in the ready meal food industry. Resour Conserv Recy 54:1196–1207

Canals LM, Muñoz I, Hospido A, Plassmann K, McLaren S (2008). Life Cycle Assessment (LCA) of domestic vs. imported vegetables. Case studies on broccoli, salad crops and green beans. Rural Economy and Land Use (RELU) Project RES-224-25-0044. Centre for Environmental Strategy, University of Surrey, Surrey. http://www.surrey.ac.uk/CES. Accessed April 2016

Carlsson-Kanyama A, Ekströmb MP, Shanahan H (2003) Food and life cycle energy inputs: consequences of diet and ways to increase efficiency. Ecol Econ 44:293–307

Chatterjee R, Sharma V, Mukherjee S (2015) The environmental impacts and allocation methods used in LCA studies of vegetable oil-based bio-diesels. Waste Biomass Valor 6:579–603

Curran MA (2006) Life cycle assessment: principles and practice. National Risk Management Research Laboratory. U.S. Environmental Protection Agency

Davis J, Sonesson U (2008) Life cycle assessment of integrated food chains—a Swedish case study of two chicken meals. Int J Life Cycle Assess 13:574–584

Ecoinvent centre (2016) Ecoinvent database. http://www.ecoinvent.org/database/database.html. Accessed April 2016

European Union, 2006 Reference document on best available techniques in the food, drink and milk industries (FDM BREF). http://eippcb.jrc.ec.europa.eu/reference/BREF/fdm_bref_0806.pdf. Accessed April 2016.

European Union (2008) Council Regulation (EC) 2008/1 of 15 January concerning Integrated Pollution Prevention Control (IPPC)

European Union (2009) Council Regulation (EC) 2009/29 of 23 April 2009 amending Directive 2003/87/EC so as to improve and extend the greenhouse gas emission allowance trading scheme of the community

European Union (2010) Joint Research Centre, Institute for Environmental and Sustainability. ILCD handbook: analysing of existing environmental impact assessment methodologies for use in life cycle assessment, 1st edn

Foster C, Green K, Bleda M, Dewick P, Evans B, Flynn A, Mylan J (2006) Environmental impacts of food production and consumption: a report to the Department for Environment, Food and Rural Affairs. Manchester Business School, Defra, London

Foteinis S, Chatzisymeon E (2016) Life cycle assessment organic versus conventional agriculture. A case study of lettuce cultivation in Greece. J Clean Prod 112:2462–2471

Frischknecht R, Steiner R, Jungbluth N (2009) The ecological scarcity method eco-factors 2006. A method for impact assessment in LCA. Federal Office for the Environment FOEN, Bern, Switzerland

Fusi A, Castellani V, Bacenetti J, Cocetta G, Fiala M, Guidetti R (2016) The environmental impact of the production of fresh cut salad: a case study in Italy. Int J Life Cycle Assess 21:162–175

Garnett T. (2006) Fruit and vegetables & UK greenhouse gas emissions: exploring the relationship. Working paper produced as part of the work of the Food Climate Research Network. Centre for Environmental Strategy, University of Surrey, Surrey

Girgenti V, Peano C, Baudino C, Tecco N (2014) From “farm to fork” strawberry system: current realities and potential innovative scenarios from life cycle assessment of non-renewable energy use and greenhouse gas emissions. Sci Total Environ 473–474:48–53

Goedkoop MJ, Spriensma R (2000). Eco-indicator 99, a damage oriented method for lifecycle impact assessment, methodology report (update April 2000)

Goedkoop MJ, Heijungs R, Huijbregts M, De Schryver A, Struijs J, Van Zelm R, ReCiPe (2008). A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level; First edition Report I: Characterisation, 2008

Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn JA, van Duin R, Huijbregts MAJ (2002) Eco-efficiency in industry and science. In: Guinée JB (ed) Handbook on life cycle assessment: operational guide to the ISO standards. Kluwer Academic Publishers, Dordrecht. (Hardbound, ISBN 1-4020-0228-9; Paperback, ISBN 1-4020-0557-1)

Gunady MGA, Biswas W, Solah VA, James AP (2012) Evaluating the global warming potential of the fresh produce supply chain for strawberries, romaine/cos lettuces (Lactuca sativa), and button mushrooms (Agaricus bisporus) in Western Australia using life cycle assessment (LCA). J Clean Prod 28:81–87

Hauschild M, Potting J (2005) Spatial differentiation in life cycle impact assessment—the EDIP2003 methodology. Environmental News no. 80. The Danish Ministry of the Environment, Environmental Protection Agency, Copenhagen

Hayashi K, Gaillard G, Nemecek T (2006) Life cycle assessment of agricultural production systems: current issues and future perspectives. p 98–110. http://www.agnet.org/library.php?func=view&id=20110721140039. Accessed April 2016

Hunt RG, Franklin WE (1996) LCA-how it came about, personal reflections on the origin and the development of LCA in USA. Int J Life Cycle Assess 1(1):4–7

ISO (2006) (a): ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization, Geneva, Switzerland (2006). (b) ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and guidelines. International Organization for Standardization, Geneva, Switzerland (2006)

Itsubo N, Atsushi I (2004) LIME: a comprehensive Japanese LCIA methodology based on endpoint modeling. 6th International Conference on Ecobalance in 2004. pp 87–88

Jensen AA, Hoffman L, Moller BT, Schmidt A (1997) Life Cycle Assessment. A guide to approaches, experiences and information sources. Environmental Issues Series, n° 6

Jolliet O, Margni M, Charles R, Humbert S, Payet J, Rebitzer G, Rosenbaum R (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J LCA 8(6):324–330

Jungbluth N, Tietje O, Scholz RW (2000) Food purchases: impacts from the consumers’ point of view investigated with a modular LCA. Int J LCA 5(3):134–142

Karakaya A, Özilgen M (2011) Energy utilization and carbon dioxide emission in the fresh, paste, whole-peeled, diced, and juiced tomato production processes. Energy 36:5101–5110

Kemna R, van Elburg M, Li W, van Holsteijn R (2005) Methodology study eco-design of energy using products. Final report. Delft, The Netherlands

Keskinen LA, Burke A, Annous BA (2009) Efficacy of chlorine, acidic electrolyzed water and aqueous chlorine dioxide solutions to decontaminate Escherichia coli O157:H7 from lettuce leaves. Int J Food Microbiol 132:134–140

Klöpffer W (1997) Life cycle assessment. From the beginning to the current state. Environ Sci Pollut Res 4(4):223–228

Larson K (2009) Eco trends in the food industry. Cereal Foods World 54(2):55–57

Lewandowska A, Fohynowicz Z, Podlesny A (2004) Comparative LCA of industrial objects part 1: LCA data quality assurance—sensitivity analysis and pedigree matrix. Int J LCA 9(2):86–89

Life Cycle Initiative (2016) Interactive map of LCA databases. http://www.lifecycleinitiative.org/resources/lca-databases-map/. Accessed April 2016

Lynch MF, Tauxe RV, Hedberg CW (2009) The growing burden of foodborne outbreaks due to contaminated fresh produce: risks and opportunities. Epidemiol Infect 137(03):307–315

Matopoulos A, Barros AC, van der Vorst J (2015) Resource-efficient supply chains: a research framework, literature review and research agenda. Supply Chain Manag Int J 20(2):218–236

Ministry of Agriculture, Food and Environment, MAGRAMA (2012) Análisis de Ciclo de Vida GEIs en producto agroalimentario sobre casos prácticos en cooperativas agroalimentarias españolas. Cooperativas Agroalimentarias-España, pp 1–82. http://helvia.uco.es/xmlui/bitstream/handle/10396/10831/Informe_proyecto_huella_de_carbono_final_protegido.pdf?sequence=1. Accessed April 2016

Notarnicola B, Hayashi K, Curran MA, Huisingh D (2012) Progress in working towards a more sustainable agri-food industry. J Clean Prod 28(1–8)

Pardo G, Zufía J (2012) Life cycle assessment of food-preservation technologies. J Clean Prod 28:198–207

Pereira RN, Vicente AA (2010) Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res Int 43:1936–1943

Pryshlakivsky J, Searcy C (2013) Fifteen years of ISO 14040: a review. J Clean Prod 57(15):115–123

Rodrigo A, Wesche M, Llorca I, Schol S (2014) Environmental assessment of new decontamination and sanitation techniques for fresh-cut products. Susclean project. Conference on fouling and cleaning in food processing “Green cleaning”, Cambridge

Romero-Gámez M, Audsley E, Suárez-Rey EM (2014) Life cycle assessment of cultivating lettuce and escarole in Spain. J Clean Prod 73:193–203

Roy P, Nei D, Orikasa T, Xu Q, Okadome H, Nakamura N, Shiina TA (2009) review of life cycle assessment (LCA) on some food products. J Food Eng 90:1–10

Sanjuán N, Stoessel F, Hellweg S (2014) Closing data gaps for LCA of food products: estimating the energy demand of food processing. Environ Sci Technol 48:1132–1140

SimaPro (2016). https://simapro.com/about/. Accessed April 2016

Society of Environmental Toxicology ad Chemistry (SETAC) (1993) Guidelines for life-cycle assessment: a “Code of Practice”. From SECAT workshop held at Sesimbra, Portugal

Steen B (1999). A systematic approach to environmental priority strategies in product development (EPS). Version 2000-general system characteristics, CPM report 1999:4, Chalmers University of Technology, Gothenburg, Sweden

Thinkstep—GaBi (2016). GaBi databases. http://www.gabi-software.com/databases/gabi-databases/. Accessed April 2016

Toffoletto L, Bulle C, Godin J, Reid C, Deschênes L (2007) LUCAS—a new LCIA method used for a Canadian-specific context. Int J LCA 12(2):93–102

Umberto. http://www.umberto.de/en/. Accessed April 2016

van der Voet E, Huppes G, Udo de Haes HA (2009) Allocation issues in LCA methodology: a case study of Corn Stover-based fuel ethanol. Int J LCA 14:529–539

Wenzel H, Petersen C (2004) The product, functional unit and reference flows in LCA Danish Ministry of Environment Environmental News No. 70

Williams AG, Audsley E, Sandars DL (2006) Determining the environmental burdens and resource use in the production of agricultural and horticultural commodities. Main report. Defra research project IS0250. Cranfield University and Defra. www.degra.gov.uk and www.silsoe.cranfield.ac.uk. Accessed April 2016

Wolf MA (2014) National LCA databases. Status and ways towards interoperability. Maki Consulting, Berlin

Acknowledgements

The authors gratefully acknowledge the financial support of the Spanish Ministry of Economy and Competitiveness (MINECO) through the project WATER4FOOD (CTQ2014-54563-C3-1-R).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Moreno, J., Pablos, C., Marugán, J. (2018). Quantitative Methods for Life Cycle Assessment (LCA) Applied to the Vegetable Industry. In: Pérez-Rodríguez, F., Skandamis, P., Valdramidis, V. (eds) Quantitative Methods for Food Safety and Quality in the Vegetable Industry. Food Microbiology and Food Safety(). Springer, Cham. https://doi.org/10.1007/978-3-319-68177-1_12

Download citation

DOI: https://doi.org/10.1007/978-3-319-68177-1_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68175-7

Online ISBN: 978-3-319-68177-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)